|

THE maintenance of an industry for two hundred years by one family, in the

direct line of succession and in one locality, is almost unique in the

history of western manufactures. Such a record proves that the successive

generations have displayed diligence, prudence, and enterprise; otherwise

it would not have been possible for them to have held continuously a

foremost place in the face of incessant competition consequent upon the

general advance in science, the introduction of superior constructional

materials, and the invention of new machinery. It indicates also the

maintenance of a high standard of workmanship as well as integrity and

business capacity; because time is the most important factor in proving

efficiency and in establishing credit for durability of work, without

which no reputation can be retained for such a long period.

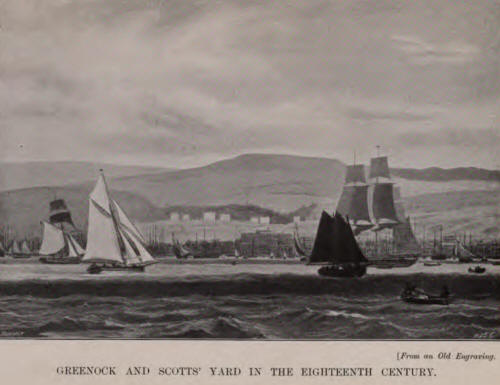

The Scotts began the building of ships in Greenock

in 1711. To-day, their descendants of the sixth generation worthily

maintain the high traditions which have accumulated during the intervening

two hundred years. It is impossible to form an adequate conception of the

service rendered by this one firm to the science of marine construction

and to Britain, the leading maritime nation of the world. We should

require to review in detail the successive steps: firstly, in the

perfection of the sailing ship, from the sloops and brigantines of the

eighteenth century, to such beautiful clippers as Scotts' Lord of the

Isles, which in 1856 made the record voyage from China, and did much to

wrest from the Americans the "blue ribbon" of the ocean; and, secondly, in

the development of the steamship from its inception early in the

nineteenth century to the leviathans of to-day. In successive epochs in

the history of naval architecture the Scotts have played a creditable

part, and to some of the more important improvements initiated or advanced

by the firm reference will be made in our brief survey of the work done

during the past two centuries. Unfortunately, some years ago, most of the

old-time records were destroyed by a fire at the shipyard, so that our

review of the early work is largely from contemporary publications, and is

unavoidably incomplete.

The beginnings were small, for Scotland had not yet

attained to industrial importance, and had little oversea commerce. The

first trans-Atlantic voyage made by a Clyde ship was in 1686, when a

Greenock-built vessel was employed on a special mission to carry

twenty-two persons transported to Carolina for attending conventicles and

"being disaffected to Government." American ships were most numerous on

the western seas, and the East India Company had a monopoly of the eastern

seas, so far as Britain was concerned, and preferred to build their ships

in India, although many were constructed on the south coast of England.

This monopoly checked progress. There was little or no incentive to

improvement in merchant ships, and the naval authorities were too busy

fighting Continental nations to risk extensive experimental work. We have

it on the authority of Sir Nathaniel' Barnaby, K.C.B.,' that neither

Government nor private builders made much progress in improving methods of

construction. The first letters patent granted for improvements relating

to ships bear the date January 17th, 1618, but the result of a thorough

investigation of all patents between 1618 and 1810 discloses no

improvement worth recording, except in the manufacture of sheathing and

the construction of pumps.

The Scotts, like a few other shipbuilders on the

Clyde, were concerned for the greater part of the eighteenth century in

the building of fishing and coasting boats. There belonged to Greenock, in

1728, as many as nine hundred of such fishing boats, locally built, each

carrying from twenty to twenty-four nets and manned by a crew of four men.

For many years the business of the firm consisted almost entirely in the

building of herring busses and small craft employed in the fishing trade,

the first establishment being at the mouth of the West Burn, on land

leased from the Shaw family. The shipbuilding industry was carried on

intermittently, and the Scotts were the first to give it stability and

continuity. In 1752, the Greenland whale fisheries were engaged in, and

this led to a development in the size of craft. The first square-rigged

vessel built in the port was a brig, named Greenock, constructed in 1760,

for the West Indian trade. In 1765, William Scott, who had succeeded the

original founder—his father, John Scott— built a large square-rigged ship

for some merchants of the town of Hull, the timber for which came from the

Ducal woods at Hamilton. This ship is notable as being probably the first

ship built on the Clyde for owners out of Scotland.2 To take a fairly

representative year (1776), eighteen vessels, ranging up to 77 tons, and

of a total of 1073 tons burden, were constructed in Greenock, and of the

number six were built by the Scotts.' Although the work could be more

cheaply done on the Clyde than at London or Bristol, there was for a long

time a strong prejudice against English owners ordering vessels from the

north, and against Scotch vessels taking any part in the oversea trade.

The Jacobite risings had also affected the industry,

but the War of Independence in America had far-reaching beneficial

results. It is true that prior to this the rich fields of the English

colonial possessions, as well as the English markets, had been opened to

the commerce of Scotland, and that the merchants of Glasgow had developed

extensive commercial operations with the West Indies and British North

America; but, although there was thus a considerable oversea trade between

the Clyde and the Western hemisphere, all the large vessels trading to the

Clyde were built in America. The shipbuilding industry in the States was

thus a very extensive one; and, in 1769, there were launched, in the North

American Colonies, three hundred and eighty-nine vessels of 20,000 tons

burden, which was far in excess of the annual British output. This was

largely owing to the limitless supply of timber in America, and to the

import duties on constructional material imposed in this country to suit

the English growers of oak, the price of which advanced in the eighteenth

century from £2 15s. to £7 7s. per load.

The Brunswick, of 600 tons, carpenters' measurement,

to carry 1000 tons real burden, built by the Scotts in 1791 for the Nova

Scotia trade; and the Caledonia, of 650 tons, built by the Scotts in 1794,

for the carriage of timber for the Navy yards—each the largest ship in

Scotland of its respective year- signalised the beginning of a period of

greater activity, especially in respect of large ocean ships. Some years

before-1767—the Scotts had feued ground for a building yard on the shore

east of the West Burn. They added a graving dock of considerable size, and

the inaugural proceedings included a dinner held on the floor of the dock.

Other developments contributed to the prosperity of

the port of Greenock, the chief of the establishment being John Scott of

the third generation, who was born in 1752, and died in 1837. His brother,

William Scott, also the second of that name, migrated to Bristol, where he

carried on an extensive trade as a shipbuilder. The latter was the father

of James M. Scott, who is still remembered by some old inhabitants as the

founder, about 1847, of penny banks in Greenock and of the Artisans' Club.

John Scott, after his brother's departure, carried on the business under

the name of John Scott and Sons, and did great service not only for the

town, but also for the advancement of the business. In three successive

years, 1787, 1788, and 1789, he bought three large plots from the ninth

Lord Cathcart, for the extension of the works.' These then extended almost

from the West Quay to the West Burn. He also, in 1791, constructed the old

steamboat or custom-house quay,2 and played a large part in developing the

banking facilities of the town. He bought, in 1815, Halkshill, near Largs,

which has continued the residence of the family. In view of the

association of the firm with the town, it may be worth interpolating here

a statement of the growth of the population of Greenock, with the sources

from which the figures have been taken.

Shipbuilding work, however, was still in craft which

to-day would be considered insignificant. The increase of the mercantile

fleet of England throughout the eighteenth century was only fivefold in

respect of numbers, and sixfold in tonnage; the average size shows an

augmentation from 80 tons to only 100 tons, and there was no improvement

in labour-economizing appliances for the working of the ship, as the ratio

of men to tonnage was at the beginning of the century practically one to

every 10 tons, and at the close one to 13 tons. [1]

In the nineteenth century, the tonnage increased

eightfold, but in view of the adoption of steam the actual carrying

capacity was augmented nearly thirtyfold; the average size of ship

increased to 760 tons. Practically, every ship in the eighteenth century

carried guns, the average being two per vessel. It was not until 1853 that

there was omitted from the mail contracts the clause which provided that

each mail vessel must be built to carry guns of the largest calibre in

use.

The nineteenth century brought every incentive to

the development of shipbuilding. Nelson taught the lesson, never to be

forgotten, that sea-power is essential to the commercial expansion—even to

the existence—of our island kingdom, with its corollary, that the merchant

fleet is as necessary to this mastery of the sea as fighting squadrons.

The sea became our home; there arose a renewed love of exploration, and an

ambition for colonisation. Succeas brought the chastening influence of

responsibility, with a higher appreciation of the advantage of a

conciliatory policy towards foreign nations. Contemporaneously with the

growth of this conception of empire there arose a war of retaliation in

shipping with the newly - formed United States of America, which continued

for half a century. Although not without its regrettable incidents, it

stimulated a rivalry in the shipping and shipbuilding industries which was

ultimately as beneficial as it had been pronounced. The monopoly of the

East India Company in the Eastern shipping trade terminated, so far as

India was concerned, in 1814, and as regards China in 1834. This removed

an influence which had hitherto retarded enterprise in naval

construction—especially on the Clyde—due to the Company's preference for

building their ships in India, and in the south of England ports. Private

owners, too, entered more vigorously into competition with American

clippers which had first commenced trade with China in 1788.

With the widening of the maritime interests and the

intensification of competition there was awakened a general desire to

increase the strength of ships. In this respect, as in others, there had

been little advance either in the Navy or in the mercantile marine. It was

exceptional for a ship of the eighteenth century to continue in service

for more than twelve or fifteen years. This was due partly to defective

constructional details, and partly to the ineffective methods of

preserving timber.

Ships were then built up' of a series of transverse

ribs, connected together by the outside planking and by the ceiling. There

was no filling between the ribs. The ship's structure thus suffered

severely from hogging and sagging stresses. The French tried to improve

this by introducing oblique iron riders across the ceiling, or by laying

the ceiling and the outside planking diagonally, while in other instances

the whole was strengthened with vertical or diagonal riders; but none of

these systems gave complete satisfaction. The Sopping system was

introduced about 1810, and was early adopted by the Scotts. The bottom of

the ship was formed into a solid mass of timber. The beams were connected

with the side of the ship by thick longitudinal timbers below the knees,

and by other stiffening members. A trussed frame was laid on the inside of

the transverse frame in the hold of the ship, and the decks were laid

diagonally. These members bound the ship in all directions, so as to

resist the stresses due to the ship working in a seaway.

The method of preserving the timber adopted at the

beginning of the eighteenth century was to char the inner surface of the

log, while the outer surface was kept wet; but this was superseded early

in the century by the stoving system, which consisted in placing timber in

wet sand, and subjecting it to the action of heat, for such time as was

necessary to extract the residue of the sap and bring the timber to a

condition of suppleness. This process continued until 1736, after which

the timber itself was steamed. Copper sheathing was first employed on

warships in 1761; prior to this lead had been used, but only occasionally.

American shipbuilders held an important position,

even in the British trade, for some time after the Declaration of

Independence; but there was then developed a pronounced spirit of

emulation amongst the British firms, which had a marked effect on

competition in western seas. At the beginning of the nineteenth century

much of the oversea work done by the Scotts was for the West Indian trade.

The vessels were not often of more than 600 tons, but the firm continued

steadily to develop their business.

Between 1773 and 1829, the period of expansion under

the second John Scott, to which we have already referred, the output was

16,800 tons.' This output included a succession of fine ships for the West

India trade, to the order of some of the old Glasgow companies, amongst

the number being Stirling, Gordon and Company; J. Campbell and Company;

James Young and Company; and Muir and Fairlie. We may mention as typical

ships, the Grenada, of 650 tons burden, and the John Campbell, of 446

tons, built in 1806, the first ships launched on the Clyde with all

rigging in position.

Thus early, too, the Scotts had entered upon the

construction of that long series of yachts, sailing and steam, which has

brought them considerable repute, and even more pleasure, since they were

in successive generations. noted yachtsmen. In 1803 they launched the

45½.-ton cutter for Colonel Campbell, of the Yorkshire Militia, which was

pronounced one of the completest of the kind ever built in Scotland up to

that time. It may be incidentally mentioned, that the Scotts also showed

thus early their practical sympathy with the auxiliary forces of the Crown

by being at the head of the volunteer Sea Fencibles formed on the Clyde in

the stormy years of the Napoleonic wars.

As soon as the monopoly of the East India Company

was removed in 1814, private shipowners entered the lists, and the Scotts

were early occupied in the construction of Indo-China clippers. In 1818

they built the Christian, and in 1820 the Belifield, the latter, of 478

tons register, for the London and Calcutta trade. She was one of the first

of a long series. The Kirkman Finlay, of 430 tons, built in 1834, suggests

the name of a firm long and honourably associated with the development of

trade in our great Eastern dependency. The effect of competition was a

reduction in the average rate of freight per ton from India to Britain

from £32 10s. about 1773 to £10 in 1830.

The East India Company about the year 1813 paid S40

per ton for their ships, as against about £25 per ton by other traders;

the latter sum was about the same as that paid in America. The East

Indiaman had a crew in the ratio of one to 10 or 12 tons, while one to 25

tons sufficed for the West Indiaman. The speed of the western ship was

greater, largely by reason of the difference in proportions and lines. The

clipper built on the Clyde and in America had a length equal to five or

six times the beam, against four times the beam in the case of the East

India Company's ships. In the design of these clippers the Scotts took an

important part. Charles Cuningham Scott was then at the head of the

concern. An ingenious method of making model experiments in the graving

dock at the works was evolved in the 'forties, whereby the firm were able

to arrive at the most satisfactory form of hull to give the minimum of

resistance, and at the same time a large capacity for cargo per registered

ton. In this latter respect they were more successful than the designers

of the East Indiamen, notwithstanding the bluff form of the latter.

As rapidity in answering the helm was a most

important element in tacking, and therefore in speed, the firm about this

time prepared full-rigged models, about 5 ft. long, for experimental

trials as to the ship's form and rudder, on Loch Thom, on the hill above

Greenock, in an exposed place where the conditions of wind were analagous

to those at sea. The results proved satisfactory. In fact, in these years,

when the Minerva, Acbar, and other noted clippers were built, the care

used in design and construction was almost as great as that now devoted in

the case of racing yachts.

The Scotts, in the first half of the nineteenth

century, continued to produce a long series of successful sailing ships,

while at the same time taking a creditable part in the evolution of the

steamship. Steam, however, was not possible in long-distance voyages until

pressures had been increased, and coal consumption reduced to moderate

limits; and thus it came that, although the steam engine was used in the

early years of the nineteenth century in river, and later in coasting,

craft, the sailing ship continued supreme almost until the middle of the

century. We do not propose, however, to refer to all of the later sailing

ships built by the Scotts, but it may be interesting to give some details

of the construction.

American rock elm was largely used. The frames were

in three sections with scarfed joints, bolted together, the scantlings

being reduced towards the top, so as to lower the centre of gravity.

Inside the frames there were at various heights longitudinal timbers, to

add to the fore-and- aft strength. The top sides were of greenheart, the

beams of oak or greenheart, with wrought-iron knees; the height between

the beams was made to admit of two hogsheads of sugar being placed in the

hold. There were side-stringers, sometimes 10 in. thick, between the floor

and the beams, which were half-checked into the stringers. On the top of

the beams there were deck-stringers. There was a most effective transverse

and longitudinal binding, brass bolts being extended right through the

knee, stringer, frame, and skin of the ship. The decks were of yellow or

Dantzig white pine. An 800 or 1000-ton West Indiaman occupied about nine

months in construction. The last wooden ship built in Greenock was the

Canadian, completed by the Scotts in 1859.

The highest conception of the iron sailing ship, as

built by the firm, was probably embodied in the Lord of the 181e8,

completed in 1856. She had a length between perpendiculars of 185 ft., a

breadth of 29 ft.—the proportion being thus 6.4 of length to 1 of

beam—with a depth of hold of 18 ft. Her registered tonnage was 691 tons,

and her builders' measurement 770 tons. Although a fine-ended ship she

carried a large cargo on board, and made her first trip to Sydney in

seventy days, which had not then been surpassed.' She made the passage

from Shanghai to London in eighty-seven days, with 1030 tons of tea on

board. In one trip she averaged 320 nautical miles for five consecutive

days. When engaged in the celebrated race for the delivery of the season's

teas from Foo-chow-foo to London, in 1856, the Lord of the Isles beat two

of the fastest American clippers, of almost twice her tonnage. She

"delivered her cargo without one spot of damage, and thus British ships

regained their asoendency in the trade which their American rivals had far

too long monopolised."2 From that time the British sailing ships gradually

gained a complete superiority over the American vessels, and carried all

before them, until they in turn were supplanted by the British steamship.

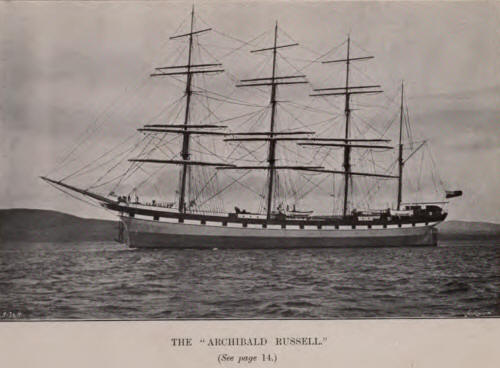

From time to time an occasional sailing ship was constructed of steel; the

latest, the Archibald Russell, is illustrated. Built for Messrs. John

Hardie and Company, this vessel has a length, between perpendiculars, of

278 ft., a beam of 43 ft., and a depth, moulded, of 26 ft., and carries

3930 tons of deadweight cargo on a draught of 21 ft. 7½ in. But less than

1 per cent. of ships now constructed depend upon the unbought but

uncertain winds, and then only for special trades. On regular routes the

steamer is now almost paramount, and it was, therefore, appropriate in the

highest degree that the first vessels to steam regularly to China, via the

Cape, should, like the Lord of the Isles, be built by the Scotts; but that

belongs to another story.

|