|

In these days of great

factories and concentration of labour in the production of articles

required for the daily use of man, it may be interesting and profitable

to recall some of the old and peculiar modes employed by our countrymen

for providing food, clothing, ami implements, but which modes have now

almost disappeared.

Machinery, driven by

steam, has done away with much hand labour, and, under the guiding hand

of man, does nearly all the work, where mechanical power is required,

and thus gets rid, in a large degree, of the great waste involved in

manual labour. This centralised production has tended to enlarge and

extend our towns and seats of industry, and to produce articles for the

million at a relatively much less cost than could be done by hand

labour, and, by means of transport and commerce, to send machine-made

articles into the furthest corners of the earth, civilised and

uncivilised; hence we find ranged alongside stone and flint implements,

the latest gay and fancy fabric of Manchester and Birmingham. Even the

Hindoo and Chinaman’s gods and idols are manufactured in our British

workshops, and many other articles which are considered peculiar to

certain nations. I had occasion to remark this particularly in a

Liverpool counting-house, for on asking what were the goods they

exported from this country, a drawer was pulled out and samples

displayed. These consisted of Spanish hedalgos, spurs, and brilliant

saddles, and saddle cloths, Spanish mantillas, <fec., of gorgeous and

rich colours, such as that noble animal the “British Crocker,” always

declares the British manufacturers can neither rival nor approach.

It is extremely

interesting to study the progress from primitive machinery to the most

advanced and intricate results of modern times, and perhaps the

Highlands of Scotland afforded till recently a very good field for such

study.

The Lowlands of Scotland

long retained their ancient practices as regards homemades, and I can

myself recall the time before the modern lucifer match and vesta were

introduced, fire was produced by various simple methods, and when the

old gaberlunzie man wandered round the country, and the chapman paid his

accustomed visit to supply jewellery, and such literature as was then

read, the old cruize lamp with fish oil and rush which supplied the poor

flicker of light to permit the maids to spin and the hinds to read.

In the Highland Glens the

primitive native arts were continued to even a later date than in the

Lowlands. This would naturally arise from the difficulty of

intercommunication in consequence of the want of roads and sparseness of

population. Accordingly we find the old manners and customs remaining,

and the old modes of cultivation being practised long after they had

disappeared from amongst their more advanced countrymen. It is to these

practices I would now draw your attention to-night, and perhaps it may

be the simplest way and most instructive if I take a glance at a few of

the more useful and common arts and discuss each in detail.

Beginning with 1st,

dwellings and utensils ; 2nd, agriculture; 3rd, food; 4th, clothing; 5th

luxuries; and 6th, articles of commerce.

I cannot expect to

exhaust any one of these subjects, but I may touch on a few of each.

The dwelling or shelter

naturally conies amongst the first requirements of a race, and the

implements necessary to procure food and clothing.

I need not go into the

very early forms of lake, dwellings, traces of such being found in

almost all the islands, natural and artificial, in our lochs under the

name of crannogs. Nor shall I touch on the beehive and eird houses so

common in Aberdeenshire and Caithness, and into which the early Pict

could barely crawl. By the way, Pennant says the origin of the name Pict,

is from Picteich a Thief—an origin, I daresay, some of you may be

inclined to dispute. Their houses were simply little domes of stone 8 or

10 feet diameter, into which the native crept and lived in the rudest

and most primitive fashion. At this stage only the simplest instruments

were available, such as stone hatchets and hammers, Hint arrow heads,

bone needles, &c., yet by means of these and the action of tire the

ancient savage was able to cut down trees, scoop out and form them for

canoes, dress stones to form the quern, and rubbing stones to bruise and

grind the grain and roots for food. He was also able to form a mortar

pestal of stone, and by fish bones form needles to sew the fibre of

various plants and hooks wherewith to catch a further supply of fish.

A little further on and

metals came to his aid, and we find bronze and iron taking the place of

stone implements, and gold and silver ornaments coming into use, many of

them exhibiting very high culture and taste.

"When our forefathers

took to roofing their dwellings with timber instead of stone, the form

seems to have been generally circular, and we have, this type in the hut

circles, which, as a rule, are just of sufficient diameter to permit the

space to be covered in by cabers placed on the ground or low turf dyke,

and to converge at the top into a point, and so far a tent, or like a

conical house. This would seem to have been the usual form of dwelling

of the native Briton at the time of the Roman Invasion, for we find the

“Candida Casa” at Whithorn of St Ninian in the sixth century much

thought of as the first stone and lime built whitehouse.

In England the progress

in castle building and also of church work was progressive, and

culminated in the grand cathedrals and castles of the thirteenth

century.

In Scotland the progress

was not so marked and steady, and we have no church work to show older

than the eleventh century, nor of domestic work anything so early. I

would, however, remark, that from the beginning of the eleventh century

till the sixteenth century, Scotland can hold her own with any country

both in ecclesiastical and baronial architecture. Still alongside the

great advances made in baronial and ecclesiastical architecture the

peasantry lived in rude huts and retained many of their old modes of

working, and continued to supply themselves with homemade stuffs, both

of food and clothing to an extent, and in a manner which it would

perhaps be well if our modern natives could still to some extent imitate

and adhere to. The farm house of the last century, and also the cottage

of the crofter, was supplied with a rude plenty, and a variety both of

food and clothing, which, if not so elegant as that of the present day,

was in many respects more healthy and serviceable for family wants,

while the mode by which everything was turned to account and rendered

available for food and clothing, forms an entertaining and useful line

of study.

The old farm house

kitchen on a winter night of itself gives a very perfect picture of what

I would like to bring before you, and let us for a moment describe it,

as I myself can remember one nearly half-a-century ago in Forfarshire.

The kitchen was a stone floored apartment, with a large fireplace,

sufficiently capacious for a fire of wooden logs, which burnt on the

hearth, and to permit of one or two sitting alongside it in the recess.

Possibly, when the farm servants gathered in at night, light would be

desirable, but there were no candles allowed, except for the ben end

(that was the portion occupied by the family of a farmer when he was of

sufficient standing to live apart from the farm servants), and how to

produce light became the question. In the poorer districts the old bog

fir was made to do duty, and the Peer man had to hold it. Those of ynn

who had the pleasure of hearing Mr James Linn, of Keith, lecture on Peer

men, will recollect his very interesting paper and beautiful specimens

of stands of iron which were made to supersede the Peer man or boy who

used to hold and replenish the bog fir, or “white candle,” when it came

into use, for it was the good old practice in Aberdeenshire to make the

beggar, or gaberlunzie man pay for his night’s quarters by keeping the

bog fir or candle alight, while others worked or amused themselves, and

hence the saying of an unsociable person, “He’ll neither dance nor hand

the candle.”

To return to house

building, as you no doubt are aware, the crofter to this day builds all

his own house—it varies in different localities. In the Lowlands, the

farm labourer’s cottage was generally built of boulders, or round

water-worn stones, and held together with clay and straw and plastered

inside and out with a smooth coating of clay, or in some districts with

lime mortar. It was roofed with wood rafters more or less manufactured,

and the rafters again covered with slabs from the nearest saw mill,

these in their turn overlaid with divots or sods and finished with

thatch of straw. The interior was iloored with beaten clay and divided

into two or more rooms by a partition of slabs or cabers, the

interstices being filled in with clay and straw, or in more ambitious

cases, wattled with hazel and smoothened with clay. The windows were

half glazed with course glass and the lower half of timber, with doors

hinged to open for ventilation. This was the Lowlander’s cottage, but

amongst the hills and on the West Coast the house was still more

primitive, in these cases the materials had to be used of a simpler

kind. The walls are drvstane, facing outside and infilled with turf in

the heart, the roof formed of trees and cabers undressed, and roughly

fitted as the}’ came to hand. The construction was also different. When

a Highlander began tobuild his house he commenced bv fixing the main

couples at certain intervals, and the lower portion was let into the

ground like a post. To the top of these the rafters were secured 4iy a

wooden pin and tied across by a tie beam. At the apex whore the rafters

met and crossed each other was laid longitudinally a long tree or beam,

oil which the smaller cabers or rafters and thatch depended and rested,

and hence was called the roof-tree, and on it the main security of the

fabric depended, and displacing the roof-tree was certain to bring the

whole fabric to the ground, and hence, in the importance of the roof

tree, and the common and genial toast, “To the roof-tree,” no doubt had

reference to this important feature in the structure. The effect of

those old Highland roofs was extremely good and picturesque, and but few

of them now remain; they are fast disappearing before the manufactured

timber and slate. The important feature of these house's and roofs is

that they were entirely the work of the natives, and required no foreign

or skilled labour iu their production ; they were entirely the work of

the founder, who was his own architect and contractor. The cost was in

those days trifling, the labour not being taken into account; but, so

scarce was, and still is, timber on the West Coast, that a crofter

removing claims and often carries, the roof with him. The fire was

placed on a stone slab or hearth in the centre of the floor, and the

smoke allowed to find its exit through sundry holes in the roof. The

result is that a large portion condenses on the rafters of the house and

forms a rich dark brown varnish, which is utilised by the crofter as

manure, and I have seen a good picture painted with this varnish, the

effect much resembling sepia. The custom of unroofing annually is still

practised, and 1 have often seen the roof lying on the hillside getting

washed with the rain. The neighbours, on the occasion of a roofing, lend

a helping hand, and I have often seen the roof being removed in the

morning and replaced by the evening.

In the Islands, from the

greater scarcity of timber, the roof and woodwork are still further

economised, and stone takes the place of timber to a greater extent. In

Harris the walls are often 6 to 8 feet thick, being formed of stone ou

the outer anti inner face, the centre being tilled up with moss and

sods, while the roof is placed on the inner side of the walls, and the

great breadth forms a rampart on which cattle and children may disport

themselves. Travelling in Lochaber on one occasion, I asked what a

cottage would cost them. The reply was, “Well, it depends on the number

of couples, but a house could be put up for 50s., but it would take £5

to make a right one.”

At the same time as the

house was constructed by home labour, it was natural that all the

furnishings should partake of the same primitive character, and

accordingly we fin<j the materials at hand were made to serve the ends

required by simple home manufacture. After the house building, one of

the first essentials would be cooking utensils, and we find that a

simple gridiron and pot were indispensable. These were formed of

hammered metal, and these cauldrons occasionally turn up, mostly of

bronze, and this may be accounted for by the greater durability and

value of copper and bronze, and these are always found in ancient

examples to be of sheets of metal made up in pieces and riveted. Many

specimens of this still exist, but the cast iron pot has entirely

superseded them in every-day life. The native pottery seems to have held

its own to a much later date, and the Lewis pottery is well known, and

in Ivilmuir, Skye, the Rev. Mr Macgregor told me he had often watched

the natives making the craggan for family use. Sixty years ago there

were in the parish of Kilmuir only three teapots, and a single pot

represented the entire cooking apparatus of a family, in which case the

potatoes were boiled in the pot and the herrings were placed in the pot

over the cooked potatoes, and so prepared.

Dishes of all kinds were

scarcely known, and instead thereof a square board above 17 inches

across with a rim 3 inches high all round, called “Clar,” served for the

dish to hold potatoes and fish, and the family seated round a rude table

eat their meal from it. Mr Macgregor also mentions, that “In many of the

poorer dwellings there was but one horn spoon, which was handed from

member to member to help themselves in turn.” There were but few bowls,

cups, or dishes of earthenware in these humble dwellings, but many of

them had wooden cups of various sizes which they got from crews of

vessels from the Baltic. They met these vessels in calm weather, anti

got planks of wood and dishes of the kind mentioned in lieu of fresh

vegetables which they took on board.

The people of this

district were in the habit of making large pots or jars of the native

clay. These craggans were of various sizes, and some of them would

contain from three to four imperial gallons, but generally they were of

smaller size, and made to contain eight or nine great bottles.

The clay of which these

craggans were made was not found in every district, but when found large

numbers of these pots or craggans were made.

Mr Macgregor describes

the process thus:—“The clay was smooth and plastic, and when required

for use it was wrought up by the hands for hours together until it was

brought to the consistency of the putty used by glaziers. When in this

state the most skilful and tasteful of the family group commenced to

form the craggan, which they finished in less than two hours’ time. The

first part of it made was the circular bottom, which, like a circular

cake, they placed upon a broad or fiat stone, always supplying

themselves from the lump of prepared clay beside them. When the bottom

was thus formed, they rapidly built upon it all around the outer edge to

the thickness of about an inch, but careful all the time to shape it

into the form required. When finished the article was coarse, rough, and

indented with finger marks, but in order to smooth it they scraped it

round and round very gently with a knife to give it a more seemly

appearance. The inside was of course left as it was, as there was no

access to it. When the dish was finished it was put on to a safe place

to dry by the heat of the sun, and was left in that state for perhaps

some weeks, until it got properly hard. The next process was to set it

in the midst of a powerful peat fire in order to burn it, and this step

of the manufacture frequently ruined the whole concern, in consequence

of the unequal heat breaking or cracking the vessel. The burning made

the craggan harder and lighter, and quite ready as a receptacle for the

family oil. This oil formed an important item in the family economy; it

was procured from the livers of different kinds offish, it was dark in

colour, like port wine, but thin and good. The fish on arrival were

gutted, and the livers were taken out and thrown into the pot or craggan,

and left there till they melted down into a comparatively liquid state.

They then set the decayed livers on a slow fire to dissolve them

completely. In this state they poured oft' the fine oil, put it into a

cragoran, and threw the refuse on a dunghill”

These craggans are still

made in the Lewis, and I show a specimen, and some cups and saucers.

The oil was mainly used

for lighting the “cruiscan,” or lamp, and I show you a specimen of the

lamp. These lamps superseded the fir root and in their turn have been

superseded by the paraffin and modern oil lamps. As you will observe,

they are constructed with two bowls or spoons, one to hold the oil and

wick, the other to catch the drip, and by a clever arrangement the upper

bowl or spoon was made by hooking on to a series of pegs to tilt up as

the oil was consumed, and so afford a continuous supply of oil to the

wick.

The mode of producing

light was by striking a spark from a piece of flint or quartz, which

spark falling on a piece of charred linen or cotton, set it on fire, and

this again was made use of to light a rude match made of fir and tipped

with brimstone.

The making of these

matches, or “spunks” as they were called, gave occupation in the long

evenings to the male part of the family, who split up fine pieces of

fir, and dipped the ends into melted brimstone or sulphur, and thus

produced a rude lucifer match. Since these were superseded by the

paraffin and other lamps, they have been generally reduced to the mean

use of melting brimstone or sulphur for smoking of bees, and those I

have recovered were being used for this purpose by the old ladies who

kept bees.

The provision of wicks

for these lamps was of some importance, and was made of the pith of

rushes from the ditches; and I have often as a boy earned a luncheon by

gathering and peeling these. They were prepared by stripping off the

outer skin, and raising by a gentle pressure, the pith in a long piece,

very like Macaroni; these were tied in bundles and dried for use.

Food.— Following up these

notes on the Domestic Economy and Occupation, we naturally come next to

the preparation of food. Thus we have, say, the meal—Oat and bere meal

was until recently the staple food of the people in Scotland, and the

preparation of their meal formed an important industry. Mr Macgregor

mentioned, in the paper before referred to, that he recollected a time

when loaf or wheaten bread was unknown in Kilmuir. “I remember,” he

says, “when loaves of bread were made at the manse for a Communion or

Sacramental occasion, when crowds of females resorted to the minister’s

house to see the ‘aran caneach' that is, the foggy or spongy bread, and

on tasting it they did not at all relish it, as they did not consider it

to be at all so substantial as their own oaten cakes.

“The mode of preparing

the grain for meal varied considerably, the most primitive being wort

was called grad dan meal. This was prepared as follows:—The standing

oats or barley having been cut down and brought to a convenient spot,

the grain is taken in handfuls from the sheaf and held over a pot or

flat stone and set fire to, and the grain being thus parched and dried,

the slight tendril is burnt through, and the grain drops on the stone or

into the pot. This handful is kept constantly beat by a stick to

separate the grain more readily from the straw. When sufficient grain

has been collected, it is stirred about in the pot or on the stone till

quite dry, it is then fanned, and the grain so prepared for the mill.”

I need not describe to

you the quern or hand mill; it is well known as being composed of two

flat stones, the upper one revolving on a centre pin and driven by hand.

The quern has not altered in its construction for thousands of years,

and I found the Bedouin Arabs in Jericho preparing their grain in

exactly the same way with the quern as I found the girls in Benbecula

and Harris. It is often referred to in Scripture as the Jews’ handmill,

and no doubt it was a quern which Samson ground on in his prison house.

The manufacture cf these

mill-stones was of great importance, and suitable stones were carried

great distances. I have found in the outer Islands many stones, of which

the only account which could be given was, that they were Lochaber

stones, and no doubt the Margarodite schist of Glenroy is admirably

suited to the purpose, being composed of garnets embedded in a soft

matrix of a white silvery Talcose schist which wears down, leaving the

garnets projecting out like teeth to cut the grain. One of the Lochaber

quarries was situated at Bruniachan, Glenroy, where stones are still to

be seen lying about half made. At the same place are traces of iron

furnaces. And another famous quarry was in an island called Soa, to the

west of Skye, and was a sandstone grit.

The querns are still used

amongst the Islands, and I have several times come on them in full

operation, notably at Lochboisdale, where a few years ago I had the

pleasure of witnessing the whole operation. It was on a Michaelmas day,

and the barley crop was ripe. I happened to mention to the innkeeper my

desire to see the operation of preparing the “Graddan Meal,” and said

that I had heard it was the custom in Uist to prepare and eat Michaelmas

cake on that day. He said “True, and if you care you can see the process

close by.” I immediately declared myself ready for the expedition. The

darkness had set in, and I had made myself comfortable for the night,

but I resumed my boots and started over the hill, and after stumbling

over rocks and bogs for a mile or so, we came to the cottage where the

operation was being carried on. We were just in time. The grain was

being separated from the straw very much as described by Mr Macgregor,

and the husks were being taken off the grain by stirring the parched

corn in a pot, the fire still kept burning the grain, and the husking

and kiln drying were one and the same operation. After the grain had

been thoroughly husked and dried, it was winnowed and ready for

grinding. The woman who did this took the grains and dropped them gently

into the centre hole of the upper stone, while she turned it with the

other hand, and the meal was thrown out round the outer rim of the

stones. After preparing about a peck of it she gathered it up, and with

a sieve separated the meal from any seeds and impurities. She then

proceeded to bake the cake in the ordinary way, and when shaped she

spread over the upper surface some melted sugar and carroway seeds. The

baking and firing was done in the ordinary way on a flat disc of metal,

and when sufficiently fired it was cut up and handed round to the

members of the family and visitors. When warm and fresh, it was very

palatable, and I enjoyed a portion. Being much interested in the custom

and operation, I begged a bit of the cake to take home. I was presented

with a goodly portion, which I brought home on trial, and a day or two

after my arrival I was describing to some friends the operation, and

offered to allow them taste of my fare. But I reckoned without my host,

for on ordering in the bread I was informed by the serving maid that my

wife had ordered the precious cake to be thrown out to the pigs, it

smelt the house so, and I must confess that however pleasing and

attractive the cake was partaken of in a Highland bothy, fresh, and with

all the romance of the situation, yet in our refined condition it had

lost its sweetness, and became absolutely offensive. So much for our

early tastes and romantic ideas of Highland life.

Jamieson, in his work on

popular songs and ballads, gives the following graphic picture of

Highland life in the beginning of the present century, and though a

little coloured it fairly enough describes the amount of home resources

of old country life, which, alas ! is a thing of the past, and the

Highlander now depends too much on foreign produce and the regular

visits of the Glasgow steamers for his comforts. He says—“ On a very Hot

day in the beginning of autumn, the author, when a stripling, was

travelling afoot over the mountains of Lochaber, from Fort-Augustus to

Inverness, and when lie came to the place where he was to have

breakfasted there was no person at home, nor was there any place where

refreshment was to be had nearer than Dores, which is eighteen miles

from Fort-Augustus. With this disagreeable prospect he proceeded about

three miles further, and turned aside to the first cottage he saw, where

he found a hale looking, lively, tidy, little, middle-aged woman

spinning wool, with a pot on the fire and some greens ready to bo put

into it. She understood no English, and his Gaelic was then by no means

good, though he spoke it well enough to be intelligible. She informed

him that she had nothing in the house that could be eaten except cheese,

a little sour cream, and some whisky. On being asked rather sharply how

she could dress the greens without meal, she good-humouredly told him

that there was plenty of meal in the croft, pointing to some unreaped

barley that stood dead ripe and dry before the door, and if he could

wait half-an-hour he should have brose and butter, bread and cheese,

bread and milk, or anything else that he chose. To this he most readily

assented, as well on account of the singularity of the proposal, as of

the necessity of the time; and the good dame set with all possible

expedition about her arduous undertaking. She first of all brought him

some cream in a bottle, telling him, ‘ He that will not work neither

will he eat; if he wished for butter, he must shake that bottle with all

his might, and sing to it like a mavis all the time; for unless he sung

to it no butter would come.’ She then went to the croft, cut down some

barley, burnt the straw to dry the grain, rubbed the grain between her

hands, and threw it up before the wind to separate it from the husks;

ground it upon a quern, sifted it, made a bannock of the meal, set it up

to bake before the fire, and lastly went to milk her cow, that was

reposing during the heat of the day, and eating some outside cabbage

leaves ayont the hallau. She sung like a lark the whole time, varying

the strain according to the employment to which it was adapted. In the

meanwhile a hen cackled under the eaves of the cottage, two new laid

eggs were immediately plunged into the boiling pot, and in less than

half-an-hour the poor, starving, faint and wayworn minstrel, with wonder

and delight, sat down to a repast that, under such circumstances, would

have been a feast for a prince.”

The simple mode of

preparing meal is still continued, and the burning of the grain to

remove the ears of corn and get rid of the husk was practised in Skye

till very recently.

The meal thus produced

was called “graddan” meal, and was highly esteemed and sold for several

shillings more per boll than the ordinary mill-made meal, and the Rev.

Mr Macgregor told me that, in his early days in Skye, the winter

mornings were enlightened and enlivened by the appearance of the fires

of each family being alight preparing the morning food in this manner.

When the lairds established regular water mills on their estates a few

centuries ago, the millers were empowered by Acts of Parliament to

search out and break all the quern stones to be found ; and families

were only allowed to use querns and other means of grinding their corn

during stormy weather, or such causes as prevented their access to the

regular mill to which they were thirled. The gauger was also a great

enemy to the quern, for it was a source of trouble to him, by enabling

the native to prepare his malt for smuggling, an art not altogether

unknown in the present day, but rendered easier from the removal of the

malt duty.

The Government, kings,

lairds, and miller seem to have been all combined against the quern from

very early times, for not only in the following Act passed by King

Alexander III. of Scotland, viz.:—“That no man shall presume to grinde

quheit, maisloch or rye with hand mills except he be compellit by storm,

and be in lack of mylnes quhilk should grinde the samen, and in this

case if a man griiules at hand mylnes, he shall give the thretien

measure as multer! and if any man contra veins this, our prohibition, he

shall tyne his hand mills perpetually.” Of course this was to protect

the lairds who had erected water mills, and to enable the millers to pay

their rents.

From the quern up to the

laird’s mill there were various qualities of mills, and I have seen both

in Shetland and in Lewis the upright wheel at work, and I show you

drawings of it. It is called a “clappan,” from the peculiar noise it

makes as the stone revolves. The peculiarity, as you will observe, is

that the wheel is horizontal, and the axle upright, and that the upper

stone of the mill is fixed to the same axle as the wheel, exactly as if

cart wheels and axle had been set on one side, one wheel at the water,

the other at the grindstone. The house must be built over the burn of

course, so that the motion passes directly to the grinding stones. The

principle of the mill is exactly the same as any other. It is the

peculiar horizontal water wheel which marks it out from the ordinary.

At the same cottage

referred to at Lochboisdale, I was amused watching an old lady of nearly

four score preparing her snuff. She took some leaves of ordinary

tobacco, and having unrolled them and dried them till they were quite

crisp, she put them in a bowl, and with the round knob of the tongs she

ground them to a fine powder, and proceeded to regale herself with a

pinch. I was told that this was not an uncommon way of preparing their

snuff, and that they preferred it to the shop snuif from Glasgow, which

they said contained glass, which cut their nostrils and lips.

In the olden times want

of communication and means of transport imposed on all our ancestors the

necessity of laying up winter stores and preparing and preserving food,

and at Martinmas the meal girnal was filled, and the mart or cow and

other animals killed for winter use.

The preparation and

utilisation of all parts of these animals for winter use formed no small

item in the home industry, and the ingenious uses to which all parts of

the animal was put and the ingenuity it developed, must have been

beneficial to the operators. Within my own recollection I have seen the

animal killed and the hams and flesh salted ; the fat prepared and made

into candles ; the white and black puddings prepared; the horns

converted into spoons by the travelling tinkers; the skin tanned and

converted into shoes, brogues, sieves for corn, and other articles. All

these operations required a certain amount of skill and experience, and

the education of the peasantry in such arts must have prepared them, in

a singularly suitable manner, to form the best emigrants and colonists.

If I follow up this line

a little further, we shall find that the making of clothes formed also

an important factor in house work. Throughout the Highlands and in many

of the Lowland houses in Scotland, till the beginning of the century,

almost all the ordinary worsteds were prepared for the weaver, as well

as the linens, and even yet I know of some goodly stock of home-made

sheeting and linens.

In the better class the

dame had her maids to spin in the evening round the fire, and in the

Highland cottage I have seen often the old wife and her daughters busy

spinning the wool, but this is now exceptional and spasmodic. A few

years ago the Harris cloth, under the encouragement of the late Countess

of Dunmore, and other ladies, became fashionable, and considerable

quantities were forced on the market, but after the novelty had passed

away, the demand subsided. The manufacturers took tip the trade, and

with their superior appliances they produced imitations at a cheaper

rate, and a more finished article for the cockney consumer.

The preparation of these

cloths formed an important and picturesque feature in Highland life, and

almost every traveller during the last century described the process

more or less. I need not therefore go into details. After the wool was

cleared, carded, and dressed, it was the duty of the females to spin it

into worsted or threads, and the doing so gave occupation to the old and

infirm as well as the young, and grannie at the spinning wheel has

always been a favourite subject for Scottish painters and poets. The

distaff was a more ancient form of spinning, and had the advantage of

being done on the hillside, and I have met the girls herding on the

hillside and busily spinning with the distaff. The working of the

distaff is very simple and picturesque, viz.—A bundle of wool is held

under the arm and also a staff about 4 feet long, which is allowed to

project in front, and over the projecting end passes the thread of

worsted. The end hangs down a foot or two, and on a spindle is hung the

whorl or ring of stone, which is the fly-wheel, and which is spun round

from time to time and twists the wool; gradually the thread is fed out

from the store under the arm, and as spun it is rolled into a ball above

the whorl. In almost all cairns and prehistoric dwellings, these whorls

are to be found, often made of steatite, but any soft stone will suit.

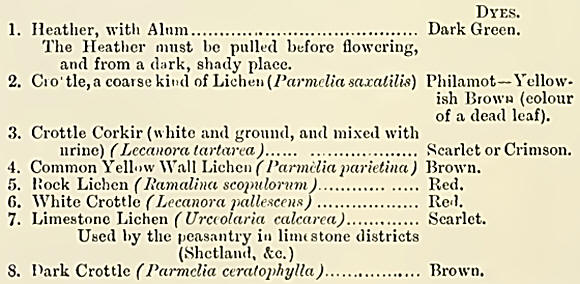

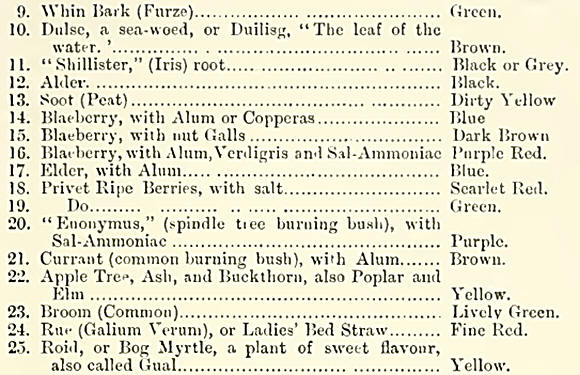

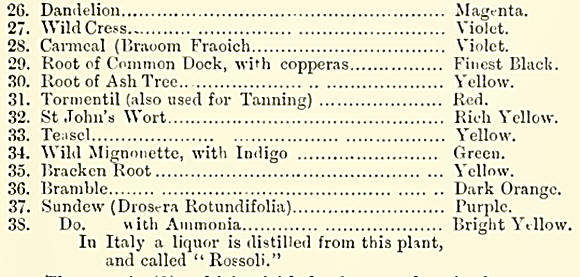

The preparation of the

wool for weaving, and also the dyeing of it, was a matter which gave

scope for much ingenuity, and I have made a list of the different dyes

used, which may be interesting. Now the mineral dyes have superseded the

native, which were as a rule vegetable, but alum, copperas, and urine

were used to clean the wool and fix the colours.

Many of the colours were

extremely bright and pretty, though it was at all times difficult to

produce the bright scarlets of the regular dyester, and amongst the

home-made cloths we find certain quantities of the brightest dyes

creeping in from the regular manufacturers. The following is, however, a

list of such dyes and their results as I have been able to procure,

viz.:—

The crottle (2), which

yielded a brown dye, is the stone and heath parmelia—Parmelia saxatilis

and omphalodes. .Another lichen which was in great favour once, and

produced a bright crimson dye, is No. 3—the corcar lichen—Lecanora

tartarea. More than a hundred years ago indigo had entirely superseded

woad to produce blue. It was with woad, or ylastum—Isalis tinctoria—that

the aucient Britons used to stain their bodies when going to battle. The

Bog Myrtle, or Myrica (25), has several Gaelic names, but on the

mainland the prevalent one is Roid. It is the badge of the Campbell

clan, and before the days of Peruvian bark, it supplied febrifuge and

worm-killing medicine not to be despised. Koid leaves are yet put in

beds and among packed-up clothes to keep away fleas and moths. It is a

highly aromatic plant. The cairmeal (28) is the orobus luberosus. A

fermented liquor was in olden times made from its tuberous roots, after

being ground down into meal.

Logwood and Redwood are

much in demand now; but these are foreign dyes, though long known and

used. I saw a dye being made in one case in Jura. The large pot was

filled with alder leaves and twigs, from which a black dye is prepared

by a simple infusion (like tea), and the colour is made fast by the

addition of logwood and copperas.

The process of dyeing

with vegetable home dyes was—To wash the thread thoroughly in urine

(long kept, and called in Gaelic “fual,”) rinsed and washed in pure

water, then put into the boiling pot of dye, which is kept hard a-boil

on the fire. The thread is now and again lifted out of the pot on the

point of a stick, and plunged back again till thoroughly dyed. If blue

the thread is washed in salt water, any other colour in fresh. The yarn

is then hung out to dry, and when dry is gathered into balls or clews,

and it is then ready for the weaver’s loom.

I am able to show you a

small bit of tartan, dyed in the Highlands 130 years ago, and used ever

since; the green being purely from the heather, the red possibly from

Crottle, No. 3.

After the wool is spun

and dyed, and the weaver has made the cloth, comes the waul king or

felting of the cloth, which in manufactories is done by the waulking

mill, formerly formed of ponderous wooden hammers which beat the cloth

in a damp state till the open wove cloth is closely felted together and

made a suitable protection against wind and rain. In the Highland

districts women make use of their feet to produce the same result, and a

picturesque sight it is to see a dozen or more Highland lassies set

round in two rows facing each other. The web of cloth is passed round in

a damp state, each one pressing and pitching it with a dash to her next

neighbour, and so the cloth is handled, pushed, crushed, and welded as

to become close and even in texture. The process is slow and tedious,

but the ladies know how to beguile the time, and the song is passed

round, each one taking up the verse in turn, and all joining in the

chorus. The effect is very peculiar and often very pleasing, and the

waulking songs are very popular in all the collections.

I have on various

occasions watched the waulking process, but seldom in recent years. It

i3 often the occasion of a little boisterous merriment and practical

joking, for, should a member of the male sex be found prowling near by,

he is, if caught, uncoremoniously thrust into the centre of the circle

and tossed with the web till, bruised with the rough usage and blackened

with the dye, he is glad to make his escape from the hands of the

furies.

Linen.—The growing of

lint, which had formed a valuable and extensive feature amongst the

peasantry, came to an end some 30 or 40 years ago, and, except as an

experiment, it is never grown now.

It was introduced some

400 or 500 years ago, and was universally cultivated throughout

Scotland. The first I have an account of in this quarter is at Portsoy,

where lint was first grown in 1490. In 1686, to promote the use of

linen, an Act was passed ordaining that no corpse of any person

whatsoever be buried in any shirt, sheet, or anything else, except in

plain linen, the cost not exceeding 20 shillings Scots per ell. The

nearest deacon or elder of the parish, with one or two neighbours, were

required to see that this was complied with.

The cultivation of lint

or flax became a national industry, and lint was grown on almost every

farm in Scotland, and it was to promote the linen trade that the British

Linen Company was commenced in 1746—it is now, as you are aware,

entirely a banking company. Factories were established in every

district. We had an extensive trade in Inverness, and mills were built

at Cromarty, Spinningdale, and as far north as Kirkwall and Stornoway.

Pennant gives a statement of the various quantities manufactured in each

county and town, and accordingly we find that Inverness, when at the

height of its prosperity in 1770-71, produced 223,798 yards, at an

average price of 6d. per yard, or a total value of £6425. 5s. 2d. I can

remember the Citadel buildings and Factory, now Albert Place,* filled

with handlooms; but Forfarshire seems to have been the great seat of

this trade in Scotland. In my early days, in Forfarshire I used to see

the lint grown and steeped in pools, or “ lint pots” as they were

called, and every village and clachan had its handloom weaver, and from

whom as boys we used to beg a bunch of threads, or “thrums,” as they

were called, to make cords and strings, and every old wife span the lint

to supply the household linen. Much of this old linen still remains in

old families, and my grandmother’s entire family linen was home-made.

The quality of this linen

was very superior, and the beauty of the patterns and artistic character

of the designs is surprising. I have been favoured with some very fine

specimens from Mr Roderick Maclean, of Ardross. These I show you were

grown at Bedcastle and Conan in the years 1810-20, and woven by hand*

These latter buildings, I am informed, were used for cotton thread

spinning—not linen weaving loom weavers in Inverness—that from Conan

woven by one Mac-phail, hand-loom weaver, in 1855, he being then about

seventy years old, and was his last weavings.

Perhaps the most

interesting is a tablecloth lent me by Mrs Aitken, which bears the name

of Marion Elliot, 1722, and a specimen, 1754, of very fine quality. I

might multiply specimens, but time will not permit.

Potatoes.—A debate arose

after Mr Maclean’s paper on “Rosskeen,” the other evening, on the

cultivation of potatoes, and as this is an important article of food in

the Highlands, I shall make a few notes as to the introduction of this

valuable and universal industry, as it has had a very important effect

on the habits and mode of life in the Highlands. The potato was at first

viewed with jealousy and dislike, and began to be cultivated with

hesitation, about its moral character, for it was believed “that some of

the more uncontrollable passions of human nature were favoured by its

use.”

It is said potatoes were

first introduced into Ireland about 1585, by Sir Walter Raleigh, and so

extensively cultivated there that they were a succour to the poor when

their cereal crops were destroyed by the soldiers during the civil war.

The exact date of the introduction of potatoes seems uncertain, for

Martin in his “Western Isles” says that in 1689 potatoes were the common

food of the people in Skye. From Ireland they were introduced into

England about the end of the 17th century, and sold in 1694 at 6d. and

8d. per pound. They were first heard of in Scotland in 1701, and the

Duchess of Buccleuch’s household book mentions the esculent as brought

from Edinburgh, and costing 2s. 6d. a peck. In 1733 it began to be

cultivated in gardens. According to Chambers’s “Domestic Annals,” the

field culture of the potatoes was first practised in the county of

Edinburgh by a man Henry Prentice in 1746. Parker says:—“Potatoes were

introduced into Uist in 1743. In the spring of that year Clan Ranald was

in Ireland, and saw with surprise and approbation the practice of the

country, and brought home a cargo of potatoes. On his arrival the

servants were convened, and directions given how to plant them, but they

all refused, and were immediately committed to prison. After a time they

gave way, and agreed to plant these roots. When ripe, many of the

tenants laid these potatoes at the laird’s door, saying, ‘The laird

might order them to plant these foolish roots, but he could not make

them eat them.’ ” It was ten years later before they reached Barra. Some

doubt on this story is raised by the fact that Martin in his description

of the "Western Isles says that in 1G89 they were the ordinary food of

the common people in Skye at that date.

Kelp. - One of the most

important industries was Kelp. From the eighteenth century, kelp was the

great staple of Highland export, and during the war in the beginning of

the century, the kelp stores yielded over 5000 tons of kelp, at the

average price in the market of £16 per ton, yielding not less than

.£80,000, exceeding five times tho rent of the thirty thousand acres of

Hebridean arable land.

Since the introduction of

Spanish barilla and other substitutes, kelp fell in price from

two-thirds to one-third of the former average, but as it is manufactured

at a cost only of from £3 to £4 per ton, it is still produced in the

Hebrides, and along the West Coast of Scotland.

Mr Macleod, the late

proprietor of Harris, in a letter to Lord Glenelg, then Secretary of

State, dated April 10th, 1829, says:— “The production of and manufacture

of kelp, which has existed more than 200 years, had for a great length

of time received a vigilant and special protection against the ai tides

of foreign or British growth or manufacture, which compete with it in

the market, namely, barilla, pot and pearl ash, and black ash, the last

of which is formed by the decomposition of salt, effected chiefly by the

use of foreign sulphur, which sulphur forms three-fourths of the value

of the manufactured alkali.”

Up to the year 1822,

considerable duties were leviable on all the commodities just

enumerated, but in that year the duty on salt was lowered from 15s. to

2s. a bushel. Shortly afterwards the impost on barilla was considerably

reduced. This measure was quickly succeeded by a repeal of the remainder

of the salt duties (duties which had lasted more than 130 years), and of

the duty on alkali made from salt. Close upon this followed a

considerable reduction in the duty on pot and pearl ash, and an entire

removal of that on ashes from Canada, and this last step was accompanied

by a diminution in the duty on foreign sulphur from £15 to 10s. a ton.

Such is the succession of the measures which now threatens the total

extinction of the kelp manufacture, and with it (in reference to

Scotland alone) the ruin of the landed proprietors in the Hebrides and

on the West Coast, the most serious injury to all descriptions of

annuitants on kelp estates, and the destitution of a population of more

than 50,000 souls. Mr Bowie, in his evidence before the Select Committee

on Emigration in February 1871, says —“I know one estate where formerly

1100 tons of kelp were manufactured annually, another where 1200 tons

were manufactured annually; and assuming that the price got at market

was only £15 a ton, taking the expense of manufacturing and conveying to

market at £3, we had there a profit of .£12 a ton; so in the one case we

should have a profit to the proprietors of £13,200 a year, and in the

other case a profit of £14,400, and this independent of the land rental.

But the whole of that kelp rental has vanished, the proprietors are

reduced to their nominal land rental, and while so reduced to their land

rental they have thrown upon their hands a large surplus population,

whom they cannot assist, and for whom they have not the means of

employment.”

The mode of manufacturing

kelp I shall describe, as it is, though often referred to, little known

beyond the shores where it is collected and manufactured.

It is a very interesting

sight on a fine summer day to see the little groups of busy men and

women along the shores collecting and keeping alight the dried sea weed,

and the smoke rising high in the air, or drifting in picturesque clouds

across the hillocks, forms a sight to be long remembered, whilst the

odour of iodine strongly taints the air, and the pungent flavour is not

unpleasing.

About the year 1862 the

British Sea Weed Company, Limited, built chemical works at Dalmuir, near

Glasgow, and took a lease of the North Uist shores from Sir John Orde,

paying as a Royalty £1000 a year, for the right of getting all the kelp

made on the North Uist shores.

In 1865 over 1200 tons

were made in North Uist and shipped to Glasgow; the price paid to

crofters and cottars was from 35s. to 63s. per ton. For the following

eight years the average amount of kelp made in North Uist was about 900

tons.

On the east side of North

Uist there is a number of bays and islands, round which a great quantity

of what they call cut or black sea weed grows on the inshore rocks and

stones.

The weed is cut once in

three years, that is to say, the part of shore cut this year will not be

cut again for three years, so as to allow the weed to grow to a full

ripe crop.

The crofters and cottars

remove from their homes to the stores of these bays and islands and live

in sheilings during kelp making, generally from 15th June till 10th

August.

The first thing to be

done is to roof the old sheiling and make it as comfortable as possible

for from four to six people to live in for two months. When the tide is

out, the weed is cut from the rocks and stones with a common corn hook;

they take a heather rope and warp it all round with sea weed, and

stretch it outside where they are cutting the sea weed. When the tide

comes in, the rope and sea weed float, and at high water they drag at

both ends of the rope and pull it ashore, with the sea weed enclosed, as

salmon fishers do when dragging for salmon in the River Ness.

When the tide goes back

from the weed that is thus taken ashore, the weed is put into creols on

horses’ backs, and sometimes on men and women’s backs, and spread on the

grass to dry, and treated as hay is treated, until it is dry enough to

burn.

When ready for burning,

say a quantity to make a ton of kelp, a trench is formed, which is

called a kiln, 12 to 24 feet, by 2 feet 6 inches by 2 feet deep, the

sides and ends formed with stones, the bottom having a layer of turf.

The weed is set aburning by a little straw or heather ; the weed has to

be kept on constantly to keep down the flame as much as possible, and

exclude the air from the burning mass inside.

The heat is intense

during the four to eight hours’ burning. Men and women do the burning;

some women are better burners than men. When the kiln is full of burning

sea weed, two or three strong men rake, mix and pound the whole mass

together with iron clubs, having long handles. When this is done, the

kiln is covered over with sea weed and stones to keep the kelp dry. In

twenty-four hours, although still hot, it can be broken into large lumps

and shipped, if a vessel is waiting. The kelp is weighed by the kelp

officer on board the ship, 22½ cwt. to the ton. This extra 2| cwt. is

put on for stones, sand, or gravel, which sometimes find their way into

the kelp, and not always unknown to the helper, especially in Ireland;

lately 20 cwt. per ton is the rule.

Drift or red weed comes

ashore on the west or Atlantic side of the Islands, during the whole

year. In winter the farmers and crofters use it for manuring their land,

from June till October. It is made into kelp, when there is demand for

it. During the last five years there has been little demand for kelp.

The red weed is 50 per

cent, more valuable than the cut weed for producing Bromide of

Potassium, Iodine, Iodide, Potash, Salts, &c., &c.

The best red weed kelp

will produce 20 lbs. of Iodine per ton, cut or black weed from 3 to 8

lbs.

The principal places

where kelp is now' got from is—Donegal, Sligo, Galway, and Clare, in

Ireland ; Orkney, North and South Uist, Barra, and Tyree. There is no

cut weed kelp made in Ireland, all being drift. The price in Ireland is

from £4 to £2 per ton.

Ropes.—I shall now refer

to a few specimens of native ingenuity—specimens of which, by the

kindness of a few friends, I am able to show you. The first is a

specimen of rope made from the long fibrous roots of the bog fir which

grow in the bogs. The gentleman, Mr Robertson of Portree, who procured

it for me, said his attention was attracted to it one day by observing

that, when a boat from Rona, moored by it, at the Portree Pier, was

blown away by the wind, the rope never sank, like a manilla rope, but

floated by its own buoyancy. These ropes possess great strength, and are

thoroughly serviceable. The root is split up into long thread-like

fibres, and then spun like ordinary hemp, and might readily be mistaken

at first sight for a manilla rope.

Locks.—By the kindness of

Mr.. Ross, Portree, I am able to show you two specimens of old-fashioned

locks, which are exceedingly ingenious, and possess tumblers and all the

leading features of a patent tumbler lock. I tried to get an old lock,

but they are not to be had, but I have been fortunate enough to find a

mechanic who could make them. These locks are in common use in St Kilda,

and I found them on all the barns and byres, though of less perfect

construction than the specimen shown.

Clocks.—The next is a

wooden clock made entirely of beech-wood; all the wheels and cogs are of

wood, except where for axles and escapement a small amount of steel and

brass are introduced, and these seem to be bits of ordinary stocking

wire.

It has been kindly lent

me by Mr William Sutherland, of Lochcarron, and he says it belonged to

his great-grandmother, and was brought by her from Fairburn, in the

parish of Urray. He says—“I remember the clock very well in my father’s

house. It kept excellent time. It had a dial of wood, also hour and

minute hands of carved wood. The clock must be at least 150 years old.

If I had taken an interest in it when a boy, I might have found out the

maker’s name.”

Brogues. —The making of

brogues was a matter of some importance, and it was not unusual before

starting on a journey to sit down and make the brogues. These were

simply rough leather uppers sewed to the soles without welts, or strips

of leather which in our modern shoes are considered necessary for

attaching the soles to the upper leather, and which enables the

shoemaker to produce the elegant and highly-finished articles now made.

The old brogue maker

began by sewing the sole on to the upper leather (which he had

previously shaped) by means of along thong of leather, and when he had

done so, lie turned the shoe, while still soft, outside in, thus

concealing the sewing, and producing the finished article. These brogues

were not meant to be water-tight, but simply as a protection, and their

duration was not great.

They are now almost

extinct, and I had great difficulty in getting a specimen. I am indebted

to Mr Macphail, Glenmore, Skye, and Mr J. Macallum, Fort-William, for

the specimen now shewn.

A still more primitive

kind of shoe is still used in Shetland, namely, the “rivelan.” It is, as

you will see, a piece of untanned leather, taken while still flexible,

and tied round to the shape of the foot, and then allowed to harden. A

laee of cord is then introduced round the upper edge, and so the shoe is

held on. It is a curious contrast to see the women working in the peat

bogs, one half of them clad in modern Indiarubber goloshes, the other

half in native rivelans. The specimens shown were prepared, and worn

into shape by a young lady at Scalloway, and cost me 2s 6d.

The people in the

outlying districts had to provide themselves with most of their

utensils, and necessity made them handy and expert in many trades, and

the custom still obtains of assisting the village craftsman. I was

struck with this in Jura, for on entering one of the cottages I saw the

occupant dropping burning peat through a small hole 3 or 4 inches in

diameter. On asking what was the object of this, I was informed he was

making peat charcoal. I examined the process and found that below this

hole was a small chamber about 2 feet in diameter, built of stones about

20 inches deep, and covered with a flat stone very much like the upper

stone of a quern.

The peats are burned to a

red heat in the open fire and then dropped in all aglow through the

small hole inferred to, and when the chamber is quite full sods are

placed over the hole to exclude the air, and so the charcoal is

prepared. This charcoal is used by the clachan blacksmith, and is said

to greatly improve the quality of iron. It is not so powerful as coal

but answers the purpose otherwise very well. The arrangement with the

smith is peculiar. There were twelve tenants in the clachan or club

farm, and each pays the smith 15s. per annum for his work, the smith

being bound on his part to do all jobbing for the tenants. The crofters

must each provide and bring his own fuel, blow the bellows and work the

forehammer.

In this same clachan, I

saw a peculiar kind of pigsty, made by building a hollow peat stack

against the gable of the house in the autumn. Into this hollow, which is

capable of accommodating three pigs, the young porkers are thrust

inside, where they stay over winter. Meanwhile the stack is being

gradually reduced, and by the time the peat is consumed, the pigs are

fit for the market.

Drinks.—Of the early

beverages of the Highlanders little is known. Whey was their common

drink, but tradition says that a kind of ale was made from the heather,

a punch from the mountain ash, and mead from honey. Boethius says,—

“Drinks were distilled from thyme, mint, and anise.” The heather ale was

from the tops in bloom, which contained a large amount of honey, being

cut, steeped and boiled, and fermented. Honey was also boiled with

water, and fermented; and though it is often said the art is lost,

“Nether-Lochaber” told me he had seen and drunk heather ale in Rannoch

as late as 1840. While a liquor is got by tapping the silver birch—and

this is practised at the present time— it is sometimes fortified by

spirits, and when kept resembles cider.

The roots of the “Orobus

Tuberosus,” the Cormeil or Carmel of the Highlanders, was used for

chewing to remove the feeling of hunger, and a fermented liquor was also

made from it.

Wine was also made from

currant and elder flower. I have tasted some red currant wine over 60

years’ old, very good and strong, although I was assured, on the most

reliable evidence, no spirit was ever put into it.

I had written an account

of whisky as known to the ancients, but I find that Mr. Macdonald, of

Dingwall, has so fully gone into the question in a former paper, that it

would only be repeating what has already been thoroughly done by him. I

shall, therefore, content myself with one or two remarks on this

subject, as applicable to Scotland and the Highlands.

Until the close of last

century whisky was less used than rum and brandy, which were landed on

the West Coast, and thence conveyed over the interior; indeed, it was

not till the beginning of the last century that spirits of any kind were

so much drunk as ale, which was formerly the universal beverage.

French wines and brandy

succeeded the general use of ales among the gentry.

It is said that in the

seventeenth and the early part of the eighteenth century “Inverness

enjoyed almost a monopoly in the art and practice of malting, and

supplied all the Northern counties. One half of the aggregate

architecture of the town was a huge and unsightly agglomeration of

malting houses, kilns and granaries, but from the date of the Revolution

onward, this trade suffered a gradual decline; and at one time it

threatened to involve the whole interests of the community in its fall.

So low had the times sunk even at the date of the Civil War of 1745-46,

that it looked almost like a field of ruins the very centre of it

containing many forsaken and dilapidated houses.”

Whisky house is a term,

till recently, almost unknown in Gaelic. Public houses were called

Tigh-leanna, that is ale houses, and had whisky been the common drink of

two hundred years ago, there certainly would have been some notice taken

of it in the laws affecting the Highlands, the accounts of society as it

then evisted, and more particularly in their songs, tales, and accounts

of convivial meetings which have come down to us; but there is no such

thing, while the allusion to ale is very common. It is true among the

gentry that the latter three-fourths of the last century saw a marked

increase of the use of French wines, and ale became less used.

It is not difficult to

seek and find the causes for the introduction of whisky into the

Highlands, apart from Government encouragement. The gradual improvement

of agriculture produced more grain, particularly barley, than was

required for the consumption of the country, much of the crops were

reaped in a damp and unripe state, and there being no roads it could not

be conveyed to the Lowlands, where the manufacture of whisky was largely

carried on, in a state such as to enable the farmer to pay to his

landlord a gradually increasing rent.

By Act of Parliament the

Highland district was marked out Ivy an arbitrary and imaginary line

running at the base of the Grampians. Nortli of this area no

distillation was allowed, except from stills containing 500 gallons, and

this, as a matter of course, was a complete interdict against the use of

barley legally within the area, as there was neither consumption for the

grain nor disposal of the produce, as one still in a few months would

have worked up the whole crop. However, distillation was the easiest way

of disposing of it. The people thus were forced into illegal

distillation in order that they might use their crops, keep credit with

their landlords, and acquire the more expensive necessaries for their

families, which an improving state of society demanded.

From the ill judged acts

of the Government proceeded illegal distillation, and all its

subordinate results to the people in the country.

We must distinguish

between fermentation and distillation. Fermented liquors seem to have

been known, common to all races, but the first distinct account of

distillation, was spirit distilled from wine in the 13th century. At

this time Raymond Lully of Majorca regarded it as an emanation from the

divinity newly revealed to man, but hidden from antiquity because the

human race was too young to use the beverage. The discovery was supposed

to indicate the end of the world and the consumption of all things. The

liquor was called aqua vita}. This spirit was imported into this country

soon after, and its manufacture encouraged by Government, with a view to

prevent the large export of money for French and Dutch spirits, and in

1695 the Scottish Parliament forbade the use of rum as interfering with

the “Consumpt of strong waters made of malt,” and because “the article

(rum) was rather a drug than a liquor, and prejudicial to the health of

all who drank it.”

The common drink of the

people till about 1725 was a light ale, which sold in pints (equal to

two English quarts), for 2d., and hence the name “twopenny.” At this

time 6d. per bushel of a malt tax was imposed, and the Edinburgh brewers

struck, and a riot took place. The “twopenny” grew scarce, and several

of the brewers were incarcerated in the Canongate Tolbooth, for not

exerting themselves to continue the trade of brewing. Fortunately they

thought better of it and resumed work.

In Inverness, from 1730

till 1760, the price of wine was, for claret, sherry, and port 14s. to

20s. per dozen.

Smuggled brandy, claret,

and tea were common, but in 1744 the Town Council entered strong

protests against them, as, they said, “they threatened to destroy the

health and morals of the people,” and the Councillors bound themselves

to discontinue the use of these “extravagant and pernicious commodities

in their own families.”

In 1761, a Dutch

merchantman of 250 tons, loaded with wines, brandy, spices, iron, and

salt was cast ashore on the coast of Strathnaver; all the country

flocked round, and not knowing the strength ot brandy and such foreign

liquor, drank to excess of it, and it is said that this very ship’s

lading debauched Caithness and Strathnaver to that degree that very many

lost their lives through their immoderation (see C.D.A. Annals, page

103).

In 1652 a representation

to Queen Mary was made regarding the poverty of the Presbyterian Clergy.

They nay “ Most of them led a beggar’s life and in the proceedings of

the General Assembly 1576, they were compelled to eke out their stipends

by selling ale, and the question formally put was, “Whether a minister

or reader may tap ale, beer, or wine, and keep an open tavern?" to which

it was answered, “Any minister or reader that taps ale, or beer, or

wine, and keeps an open tavern, should be exhorted by the Commissioners

to keep decorum.”

In the Glasgow Town

Accounts whisky figures as early as 1573, under the name of aqua vitae,

the quart being charged at 24s., as “The Magistrates and divers honest

men” did occasionally treat themselves to a dijitne, but this was after

the completion of some public business, tending to the honour and profit

of the common weal.

In 1697 claret sold at

10d. the mutchkin.

In 1720 the Edinburgh

prices were:—Neat claret, 10d.; strong claret, 1s. 3d.; and white wine,

1s. per bottle.

It has been said no

record exists of a home manufacture of whisky till 1708, but this does

not seem quite correct, and Inverness seems to have been well a-head of

the times, for in the Town Council books of 1650, the Council ordered

three gallons of the best aqua vita; to be distilled, and six pairs of

the best white plaids to be made and sent South, to be bestowed, by the

Town’s Commissioner in Parliament, on such as he may think proper.

An amusing conversation

is recorded between Dr Johnson and Boswell, when in Skye, regarding the

drink of the Scots. Johnson asserted “That they (the Scots) had hardly

any trade, any money, or any elegance before the Union. We have taught

you (said he) and will do the same, in time, to all barbarous nations.”

Boswell said—“We had wine before the Union.” Johnson—“No, sir; you had

some stuff, the refuse of France, which would not make you drunk.”

Boswell—“I assure you, sir, there was a great deal of drunkenness.”

Johnson—“No, sir; there were people who died of dropsies, which they

contracted, trying to get drunk.”

In 1708 about 50,000

gallons of whisky were produced, and the production went up in 1756 to

433,000 gallons. Shortly after this a demand for Scotch whisky sprang up

in England, and in 1776 an import duty of 2s. 6d. per gallon was imposed

on all spirits sent into England. Here, I think, was another cause of

smuggling, and it is stated by a recent writer that in that year 300,000

gallons crossed the Border. Of course, as the restrictions on licensed

distillers were increased, the temptations were greater to the smuggler,

and a bill was passed in 1823, sanctioning legal distillation at 2s. 6d.

per gallon, the Highland proprietors agreeing to put down illegal

manufactures. Since then the practice has gradually declined. Though we

speak of Highland smuggling, it was by no means confined to the

Highlands, though it has lingered there longest; for in Edinburgh in

1777 there were 8 licenced stills, and about 800 unlicenced.

Ferintosh smuggling was

well known and long practised in the district, and much more whisky

seemed to come from the district than could well be made. The privilege

arose from the losses sustained by the Culloden family in 1689-90,

estimated at £49,400. 6s. 8d. Scot. King William III. gave the family,

instead of money, the perpetual privilege of distilling from grain

raised on the estate for a small composition in lieu of excise. It was

known much abroad, and one author says it produced as much whisky as all

Scotland put together, and the licence was withdrawn in 1785, and a

compensation of £21,500 paid. The greatest sufferers were the Dingwall

lawyers, whose business and support mainly depended on defending

smugglers and redding quarrels from that district.

Time will not permit me

to refer at length to all the occupations of the Highlander, and his

various devices for providing for his daily wants. The merchant and

commercial traveller provides him with cheaper articles if not so good;

but I think his life has lost much of its picturesqueness, and his

ingenuity and ready-handedness seems in a large measure gone or in

abeyance. In these olden times there was ever ready at hand light,

agreeable tasks to fill up his time. His long evenings were taken up

making his brogues, a lock, ropes, fishing tackle, and hunting gear. Now

everything is purchased, and when not actually engaged in regular

employment, the Highlander spends his time in idling about his doors, or

the useless and delusive task of discussing politics, his rights and his

wrongs, which, by the way, in my experience, he knows far better than

his duties. The result of all this is that the Highlanders of the West

Coast do little for their own comfort, and it is consistent with my own

knowledge that the amount of food and luxuries brought into the Islands

is far in excess of what they were 30 years ago, and that the natives

seem to make less use of the articles ready to hand than they formerly

did. For instance, a Highlander does not kill his pig and cure it for

his family, using all the portions to the best advantage. He sells it

cheap and imports cured hams at a high rate. He does not use. his

poultry, but sells all his eggs by barter to little merchants, and

purchases tea and sugar and coffee to use in his family instead. He does

not make soup and cook the shellfish so plentiful on the coast, but

exports them for, after all, a small return, and I cannot regard it as a

good sign of the times, when everything is imported and little done at

home. For instance, in the case of the rope made of the moss roots, it

was a substantial article, and sufficiently good for its purpose, and

when asked why he did not always make and use such, his reply was, “

Ach, it’s too much bother, we can buy a hemp one easier.” No doubt this

is true, but is it wise1? During the long winter nights, the time wasted

might be profitably occupied by these home-mades, I fear the inclination

is gone, and the agitation which has been carried on for the last few

years has tended much to put a stop to these useful and economical

occupations.

At no time does the

Highlander ever seem to have had great artistic instincts, one seldom

sees a bit of ornamentation or carving, or any attempt at drawing.

Occasionally the handle

of a dirk or a walking-stick with a big crook is manufactured, but such

articles of artistic merit as the Swiss mountaineer makes in the long

winter nights in his Alpine village, are foreign to the instincts of the

Highlander; not that the skill and ingenuity are altogether wanting, but

the mind has been turned from it. An active, roving life better suits

the Celt, and the precarious life of a fisherman, in lieu of the

hunter’s, pleases him better than the drudgery of agriculture and spade

labour, and even the dangerous and risky occupation of smuggling has

greater charms for some of them than any regular employment in the long

winter nights.

I would not wish to be

understood as saying that the Scottish Highlander wants the aptitude for

adapting himself to his situation, nor the capacity of turning anything

he requires to account.

I have shown the contrary

in the foregoing notes; but I think the cessation of home work and

home-made appliances has rendered him too dependent on foreign aid, and

led him to look for outside support, when he ought to be able to help

himself, and to turn to his use and comfort much that lies ready to

hand, and which would save him actual outlay of money, and add much to

his comfort and pleasure. |