|

It is said that in India certain arts

were confined to certain families or castes, and that as

these families died out, the arts were lost. The same

thing has happened, though in a different way, in the

Highlands. When the people were divided into clans, and

lived by themselves, many arts and industries were in use

amongst them, which, from social changes and the progress

of commerce and civilisation, have passed away. The

making of cloth was once largely practised. First the

wool was prepared in the carding—mill, then it was spun

into thread, then it was dyed, and various kinds of bark

and lichens were employed to produce different dyes, then

it was woven, loom weavers being then common, then it was

‘‘ waulked," and when all was finished, it was turned to

use as required. These operations were mostly carried out

by women, and they used to lighten their labours by song.

It was said of the Roman matron, ‘‘ Domum mansit, lanam

fecit,’’ well rendered by Robertson of Struan, ‘‘ She

keepit weel the hoose, and birlit at the wheel." This was

true also of the Highlands in the olden time. The wheel

was found in every house, and pleasant it was to see

matron or maiden plying her task at the fireside with

simple grace and joy.

"Verse sweetens toil, however rude the

sound,

All at her work the village maiden sings,

Nor while she turns the giddy wheel around,

Revolves the sad vicissitudes of things."

Fuel had to be provided, and this was

chiefly taken from the mosses. Peat may be said to be

arrested coal. It is found in abundance in the cold north.

Before the days of railways the people were largely

dependent upon it for their fire. Mossing, which

was in May or June, was a lively stirring time. The

cutting was done by men from a bank with spades, and the

carrying by women and boys in light barrows. First the

peats were set up two and two together. Then when well

dried they were put in little heaps, and afterwards built

up into stacks, or carted home for use. The making of

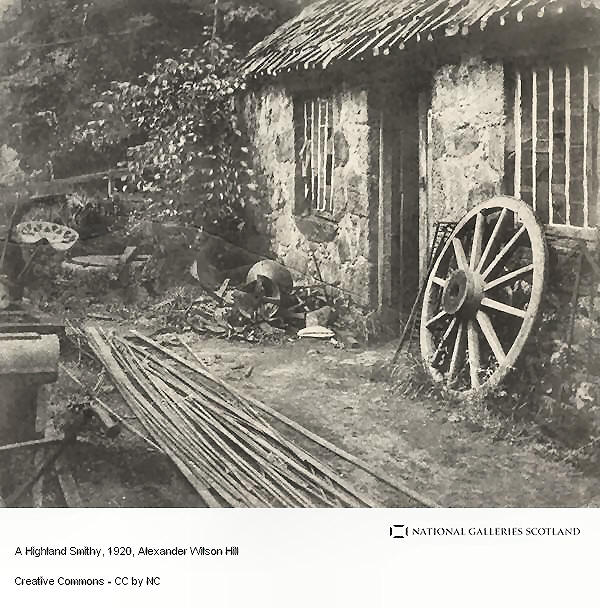

charcoal for smithies was a more complicated business.

David Laing, Causair, who came from Kinloss in 1806. used

to make his coal at Plotta, near time old Tonmintoul road,

as the moss there was found most suitable for the purpose.

Calm weather was chosen for the work. First three or four

pits were dug, and these were built up with dry peats to a

height of 5 feet above the surface of the ground, leaving

an air-hole in the centre, and then carefully thatched.

Fire was applied by the vent. Soon a kind of sough was

heard, and then the vent was covered with small peats and

dust. The fire spread from windward. The heaps were

closely watched, and wherever the fire threatened to break

through, the weak places were strengthened by divots and

gravel. But no pressure or undue weight was applied. Soon

the heat became intense. The heaps were allowed to burn

for about a week. Then the charcoal was taken out, and

carted to the smithy, where it was carefully husbanded.

The work of the bellows and the anvil could not go on

without it. Hence the Gaelic proverb, ‘‘An uair a

theirigeas gual, sguiridh obair," When coal ends, work

stops.

Tar was much used in former days,

not only for sheep and cattle, but for carts, then made

entirely of wood, and for domestic purposes. It was made

in this way. First a pit was dug in firm mossy ground,

with a round hole at the bottom about 18 inches deep, to

hold a cask or jar, covered with a flag resting on stone

supports, so as to let the tar run in from above. The pit

was then filled with cut quick—fire, rich with resin, and

covered with divots packed close with moss. The fire was

lighted from the top, but allowed to burn slowly for two

or three days. The resinous sap oozing out dropped into

the central hole. When carefully done, the tar thus

obtained was of the finest quality. The quern was

still in use sixty years ago. Another important implement

was the knocking-black. In most parts of the

Highlands it was made of stone, but in Strathspey, where

wood was plentiful, it was generally made of wood. The

mode of manufacture was simple. First, a fir tree, well

matured, was chosen, and a piece sawn off of the proper

size. Then holes were bored in the centre with an auger

(G. Tora), and the wood cut out with a chisel (C

Glib) so as to form a cup-like hole of sufficient

depth. Then the hole was smoothed and hardened by burning

peat-coals inside, care being taken by means of a damp

cloth to prevent the wood from being burnt or cracked. The

mallet was also of wood, with the point rounded, and

generally studded with nails to make it the more firm and

durable. The block was called in Gaelic "An Cnap Eorna,"

the Barley Block, and often for shortness the Cnap,

or Cnotag. The mallet was called An

teangaidh, the tongue - probably from its shape, but

perhaps with a cunning reference to the purpose to which

it was applied. It was sometimes called "An slachdan,"

the Beater. The block was worked as follows:—Some

barley was put into a dish and damped with water. It was

then rubbed with the hand, and when so far cleaned and

moistened it was put into the block and beaten with the

mallet. The operator, usually a woman, was seated, and

carried on the process very methodically—first giving a

stroke downwards upon the barley, and then a lighter

stroke on the side of the block to shake off any grains

that might have adhered to the mallet. So on she went,

with a sort of musical rhythm, often with the

accompaniment of song, till the grain was loosened from

the husk. The next step was to winnow the grain, which was

done with a fan (an dallanach). The barley

was then put into a dish with warm water, and carefully

worked about with the hand, till it was perfectly smooth

and white. It was then fit for use, and was called "Cnots,"

pronounced "Grots." Perhaps this may be the origin of the

English word "groats." A specimen of a knocking-block and

mall, from Lynamer. Tulloch, was presented to the Museum

of Antiquities, Edinburgh. Stone blocks are common, but a

wooden block is a great rarity.

WOOD MANUFACTURE.—For long this was the

chief industry of our Parish. In winter the men were

employed in felling trees in the forest, and in bringing

the logs with horses to the river bank, and to the

saw-mills. There were dams or reservoirs on the Nethy,

and, by letting off the water from them, the river was

raised sufficiently to admit of the logs that had been

laid down at convenient points being floated to the Spey.

The men employed in this way were called "Floaters." The

scene on a floating-day was very picturesque and lively.

From thirty to forty men met at the appointed place, each

of them with his "deck," a wooden pole with a two-pointed

head of iron, fitted for pushing or hauling. The logs had

been rolled into the bed of the river, and, when the rush

of water came, the utmost endeavour was made to keep them

afloat and moving. From pool to pool the men plied their

task. Sometimes a block took place. Two logs got fast

across a stone, or in some narrow place; then others were

caught and heaped up. In a second or two there was a huge

pile, jammed and locked together in seemingly inextricable

confusion. But the men knew their business. Some stalwart

lad dashed in, fastened his cleek in the log that formed

the key of the lock, tugged and strained till he got it

free, and then in a moment the huge pile broke up. and the

channel again was clear. At the Dell intack, Benjamin

Lobban might be seen standing near the sluice, and deftly

picking out such of the finer logs as he fancied, to be

sawn into deals. But the bulk of the logs were taken to

the mouth of the Nethy (Broomhill), to be made up into

floats or rafts for Garmouth. These floats were formed

after the improved pattern by Aaron Hill. They were made

up of logs fastened together, with, perhaps, a cargo of

deals, and were managed by two men, one at each end, with

long oars. When the floats were buckled, and the Spey was

of proper size, one after another would start on their

40-mile voyage. For the first four miles the water was

sluggish and the progress slow. Beyond Kirkton the river

runs more quickly, and there are strong streams here and

there, all the way to Ballindalloch, so that the pace was

more satisfactory. The fork and shallows at Advie, and the

rapids at Dalgarvan and Dundurcas, had to he carefully

watched. Mishaps and losses happened at these places, but

the men had attained, by long experience, to such skill

and expertness that accidents were very rare. The cruives,

or braes, used by the Duke of Gordon’s fishermen,

sometimes gave trouble. Once a well-known floater, of the

name of Clarke, was asked by a watcher how he got over the

brae. " Never better, never better," was the cheery reply.

The fact was the worth floater had carried his float right

through, making a big gap in the brae! The best floaters

would make the trip to the sea in about twelve hours.

Starting early in the morning from Broomhill, they would

be able, not only to get to Garmouth by the evening. but

to reach Rothes on their home journey before night. The

number of tenants employed in this industry in Abernethy

was about 90, and their earnings were considerable—often

more than enough to cover the rent of their farms. In

1839, 91 tenants were paid the sum of £452 ; and in 1840,

95 tenants received among them £636. It is evident that

great advantages to the tenants accrued under the system,

and the landlord had not only the satisfaction of giving

employment in a way that encouraged industry and thrift,

but also of obtaining a safe and easy settlement of rents.

The old system was abolished in 1843, and now the

manufacture of wood is mostly in the hands of strangers.

With reference to some of the old

industries, such as dyeing, spinning, carving, and others,

it may be observed that they were practised when work was

slack, and filled up leisure hours which might otherwise

have been spent idly and unprofitably. In the Black

Forest, in winter, men are busy manufacturing wooden

clocks; in the Tyrol, in making and painting dolls; and in

Switzerland, in various forms of wood-carving. These

industries are supplemental to the ordinary work of

the place, and do good in many ways. Something of this

kind is much needed in the Highlands, and the efforts

being made, as by the Highland Industrial Association, to

establish such crafts, are deserving of every

encouragement. It is desirable also that our system of

compulsory education, which is becoming harassing and

oppressive to small farmers and labourers, should he

somewhat modified, and that it should be recognised that

boys and girls, above 12 years of age, who are employed

agriculturally, are really receiving a technical

education, which may be of more advantage to them in after

life than much of the learning of the schools. |

|

|

|

|