|

THE one indispensable

tool in the building of a log cabin is the ax. I know a man who, with no

other implement, can erect a marvelously complete cabin; but this degree

of efficiency we ordinary people may not hope to attain.

If you be wise, then,

purchase the best ax possible. The cost of this will not be over $1.25.

An inferior one may be had as low as 75 cents, but the steel is not

there. Long before the camp is finished you will have discovered that an

ax which bites in deep and holds its cutting edge is desirable. Axes

come of varying weights, but for the average user one of three and a

half or three and three-quarter pounds is about right.

Perhaps it has not

occurred to you that the "handle" or helve was a thing to be considered,

yet the dealer will put out an assortment which, if you examine them,

will be found to consist of crooked and straight, thick and thin, and

varying combinations of these. If you have never handled an ax, you will

have some difficulty in deciding. Your only guide probably will be,

after selecting one fairly crooked, to purchase the one which feels best

in your hand. If your fingers are short, do not get a handle too large

in diameter, and trice versa. Neglected, this point may occasion you a

painful period of cramped fingers. I have seen men in the woods (and

they forget to complain of any hurt) whose grip had to be loosened by

the aid of the swinging hand. An extra helve should be taken always.

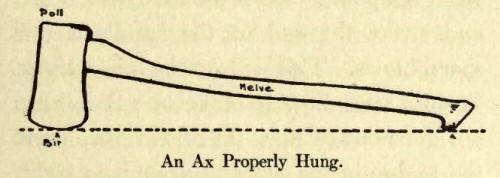

To "hang" your ax

properly requires care, and is important. If it be hung too far "out" or

too far "in," or if it be out of line, it will lessen very materially

the effectiveness of your stroke. Therefore, slip the helve into place

in the eye of the ax, work the "bit" or cutting edge up and down, to see

whether it can be brought to a proper position. This means that the

center of the bit and the knob on the handle should touch if the ax were

placed against a straightedge, as shown in the plate.

If necessary to bring

this about you will, of course, cut off a little from the back of the

helve until the ax hangs properly. Be very careful to see that the bit

of the ax comes in direct line with the helve.

About a half inch of the

helve should project through the ax on top. Now, with a chisel or

another ax, split the helve straight across from the "bit" to the

"poll," then select a piece of hardwood, of the width of the handle, and

make a wedge, rather long and about three-sixteenths of an inch in

thickness an inch and a half from the point. Turn the ax upside down and

strike the end of the handle a few sharp blows. This will set the ax on

tight. Sight it once more to make sure that it has not gone out of line.

If all is right, insert the wedge in the slot and drive it in tight.

Then with a saw cut off the projecting ends of the helve and wedge flush

with the ax. You may depend upon it, this will never come loose. A small

whetstone (one of carborundum is best) will keep the edge keen.

Occasionally, however,

the ax must come to the grindstone, for in spite of every effort to

avoid injury, the nicks will appear. Do not attempt to cut off the

knotty stubs of hemlock—they are like iron. Batter them off with the

poll of the ax.

It is best to fell your

lumber in the spring, say from May to July. At this time the sap will

run and the bark may then be easily stripped. After that, you may find

some day that it is difficult or impossible to peel the bark; then the

only alternative is to shave the bark off with a drawshave; but this

spoils the beauty of the log.

To peel the bark from a

tree or log, cut two circles completely around the log about four or

five feet apart, and connect these with another cut lengthwise of the

log. Insert the edge of the ax to start the bark. If the sap is running

well, it will strip easily, requiring but little loosening from time to

time with the ax or a "spud," which is a short stick of hard wood

tapered at one end to a flat edge.

Should the bark be

desired for roofing, it should be flattened out and kept away from the

ground to dry.

Any of the soft woods may

be used for building—pine, fir, spruce, etc.—according to the growth of

timber handiest. Maple, birch, beech, etc., will be much too heavy to

handle and hard to work.

It is a simple matter to

estimate the height of a tree by standing off a short distance and

guessing the probable height of the first branches. If they are ten feet

from the ground, make mental divisions of the tree in ten-foot lengths,

and you will be surprised how near your estimate will be correct.

Before you cut into a

tree, make sure that it does not taper too suddenly, and sight it

carefully that it may not have a bad crook in it that will make it

unavailable. Certainty here will save you much labor, to say nothing of

the regret which must come to a lover of the woods with any wanton

destruction. Keep in mind that it takes only twenty minutes to cut down

a tree, but thirty years' growth will scarcely replace it.

Having decided upon your

tree, make sure of the best direction for its fall. It is important that

it should not lodge in the branches of neighboring trees. Should such an

event come to pass, exercise every care in your effort to dislodge it. A

falling tree has a way of trapping the unwary, the results of which are

apt to be serious. Study the situation well.

Trim away very carefully

all the underbrush within the reach of your swinging ax, and thus avoid

injury. An ax diverted from its course strikes with the quickness of a

flash.

Begin to cut on the side

of the tree facing the direction of its intended fall. Your notch will

be quite wide to prevent the ax from wedging as it bites its way into

the tree, a blow from above to make the chip and a blow from below to

cut it out. Work slowly and deliberately, so that each blow may count,

but do not exert yourself unduly. Let the weight of the ax do its share

of the work. Eventually you will achieve some accuracy, and then the

stumps will approximate that planed-off appearance which a lumberman

leaves. Yours will not look that way.

When you have the notch a

little more than halfway through the tree, begin a similar cut on the

opposite side, somewhat higher than the first cut. In a thick growth you

may have to cut very deeply, but presently the tree will pitch slightly

in the direction of its fall, and at the next stroke it will crack and

settle to the earth. Step to one side when this occurs, never in the

opposite direction of its fall, for some trees have a nasty habit of

springing back from the stump, and woe to the individual in their path!

For dressing small

timber, cut two logs four feet long and about one foot in diameter. Bore

three large holes through one of these logs, two about six inches from

each end and one in the middle. Make three hardwood pins to fit the

holes, and drive one through the middle hole so that it projects about

one foot. Now fasten the pin upright by driving two more pins through

the two end holes into the ground, to hold the log firmly. The other log

should have a notch cut in the center about six inches deep.

Bore a hole through the

log to be hewn, about four inches from the end, and fit it over the pin,

the other end of the log lying in the notched stick. Snap a line for

your cut, then you should commence with your ax to "score in and beat

off" up nearly to the line. That is, strike a sharp blow with the ax

from the side of the log, slanting in toward the line, but not quite

touching it. Another blow in the opposite direction will cause the chip

to fly out. Arriving at the end of the log, begin hewing carefully to

the line. You will be surprised how quickly all this can be

accomplished. Of course, all the cutting is done on the side of the log.

The work may be made more complete now by running a plane over it once

or twice.

In the course of your

work it may be your misfortune to break the ax helve, and you will

thereby be confronted with the problem of removing the stub, which you

wedged in with the idea of its never coming out. Horace Kephart, in his

excellent book, "Camping and Woodcraft," gives a simple solution to the

problem:

"When the stub of the old

handle cannot be removed by ordinary means, it must be burned out. To do

this without drawing the temper of the steel might seem impracticable,

but the thing is as simple as rolling off a log when you see it done.

Pick out a spot where the earth is free from stones and pebbles, and

drive the blade of the ax into the ground up to the eye. Then build a

fire around the ax head—that is all."

A cant-dog and a

cross-cut saw are tools which will greatly facilitate work on logs.

Other tools which you will need on the better class of buildings are:

Handsaws—ripand crosscut, steel square, level, hammer, brace and bits,

chisels, drawshave, two-foot rule, chalk line and chalk, bevel,

compasses, large and small planes. Have your saws well sharpened and

keep a good whetstone handy, so that your tools may never become dull.

Many of the operations

connected with the building will take place in the spring, and in many

sections this is the happiest time of the year for the joyous mosquito,

the black fly, the minge, the no-see-um and ad infinitum. Some

protection from these pests is necessary, and a "dope" that can be

smeared on liberally over face, neck, ears and hands should be provided.

This is important, and overlooking so simple a thing may be the occasion

for your quitting work after the first half-hour, with the necessity of

going "to town" to repair the oversight.

There are several

varieties of " dope " on the market, and about every woodsman has a kind

of his own. They are all good so long as they will give a greasy

coating, and this must be renewed from time to time. My own concoction

is:

Oil of Pennyroyal

...................1 oz.

Sweet Oil ............................. 6 oz.

Ammonia...............................1 oz. |