|

THE work for the Navy by the Scotts began with the building, in 1803, of a

sloop-of-war named The Prince of Wales; a photograph from the model of

this vessel is reproduced on Plate XIV.

Since the construction of this ship the firm have carried out several

important Admiralty contracts, including the first machinery manufactured

in Scotland for a dockyard-built ship, the first steam frigate built in

the North, and several later ships, with their engines; the most recent

order being for the machinery of the armoured cruiser Defence, of 14,600

tons displacement, and 27,000 indicated horse-power, to give a speed of 23

knots.

The progress demonstrated by a contrast between the small sloop-of-war and

this latest powerfully-armed and well-protected high-speed cruiser, is a

record of research and invention, not only on the part of the naval

architect, but also of the chemist, the metallurgist, and the engineer;

the triumph is greater than that reviewed in the case of the Merchant

Marine. Great speed has been achieved, notwithstanding that the problems

to be solved in its attainment have been intensified by the limitations in

the size of the ship in order to minimise the target presented to the

enemy's fire, and by the necessity of providing for heavy armour,

armament, and ammunition in the displacement weight.

When a comparison is made of the Navy ships at the beginning of the

nineteenth century with those of a hundred years earlier, it is found that

little progress had been made, either in design or in gun-power. The

largest vessel in 1700 was of 1809 tons burden, with a hundred guns. A

century later, the size had increased only to 2600 tons, with a hundred

and twenty guns.' But even this was an exceptionally large vessel. The

British ships were, as a rule, smaller, and perhaps slower, than the

French ships; but then—as now and always—skill in strategy, courage in

combat, and devotion to duty were the most powerful factors in action. No

fault in these respects could be found with the work of our Navy in the

various engagements which terminated in the epoch-marking victory in

Trafalgar Bay.

The peace following the Napoleonic wars was not conducive to advancement,

as there was little incentive to pursue the sciences which contributed to

the development of destructive weapons. Steam as a motive power and iron

as a constructive material were not so readily adopted in the Navy ship as

in the Merchant Marine. Progress in the utilisation of iron was not

continuous. The first application of steam was belated, and its popularity

was not unalloyed.

The Admiralty ordered their first ship of iron in 1839—a small,

non-fighting boat for the Dover station— and there followed other vessels

for the exploration of the River Niger. But the first iron fighting ship

was not built until 1843. In 1848-9 the Scotts constructed the iron steam

frigate Greenock, the largest iron warship of her day, and the first steam

frigate built on the Clyde. The over-all length of this vessel was 213

ft., the beam 37 ft. 4 in., and the depth of hold 23 ft. She was of 1413

tons burden, and carried ten 32-pounder smoothbore muzzle-loading guns.

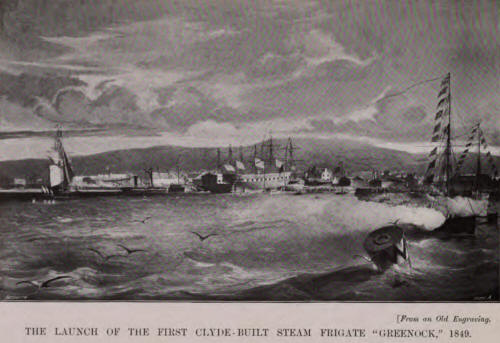

The illustration on Plate XV. is a reproduction from an old engraving of

the launch of the vessel. It is a noteworthy feature that the figure-head

was a bust of John Scott, the second of that name. This compliment by the

Naval authorities of the time was well merited, as he did much not only

for the advance of naval architecture, but also for the development of

Greenock.

As a writer of the day put it, this vessel was the experimentum crucis of

the principle of constructing fighting ships of iron.' By 1850 there were

six large iron vessels, ranging downwards from the 1980 tons of the

eighteen-gun ship Simoon, with eleven smaller vessels; but they were all

condemned, because it was found by experiment' that the 32-pounder gun at

short range could perforate the side of the iron ship, and that the

projectile carried its "cloud of langrage" with great velocity into the

interior of the ship, so that men could not stand against it. Tests were

also made with sixteen wrought- iron plates superposed, to give a total

thickness of 6 in., but these also were perforated by the 32-pounder

projectiles at 400 yards range; so that the adoption of iron on the main

structure of the ship was practically delayed until armour-plates were

first rolled in 1859.

The obstacle to the adoption of steam was the unsuitability of

paddle-wheel machinery for fighting ships. The wheel was exposed to

gun-fire, and the whole of the machinery could not be located below the

water line. Moreover, the side wheel limited the number of guns which

could be utilised for broadside fire. The first steam craft ordered by the

Admiralty was a small vessel of 210 tons and 80 nominal horse - power,

built in London in 1820.1 Several other non-fighting steamships followed.

By 1837, the largest steam vessel in the fleet was a sloop of 1111 tons

and 320 horse-power.' In 1839 five steam vessels were built, and two of

them—the Hecate and Heckiwere engined by the Scotte. These wooden steamers

were the first Naval vessels sent to Scotland to have their machinery

fitted on board. They were of 817 tons and 250 horse-power. The

paddle-wheels had a diameter of 25 ft. 4 in., and there were seventeen

floats. The main engines, illustrated on page 29, represent the type

adopted, not only in the Naval, but in the Merchant service of this time.

The steam pressure was then about 3 lb. per square inch.

On Plate XVI. we illustrate the general arrangement of the machinery in

the Hecate and Hecla. There were four boilers of the rectangular type,

each with two wet- bottomed furnaces at one end and large return flues at

the other end. The uptakes passed up inside the boilers through the steam

space, uniting in one funnel.

Smith's screw-propeller was tried experimentally in 1837, and Ericsson's

about the same time. The comparative trials of the Archimedes fitted with

Smith's screw against existing paddle - steamers did much to prove the

efficiency of the new system.8 The screw-ship excelled the performance of

paddle-steamers on the service, and the screw-propeller was adopted by the

Admiralty in 1845 twin-screws followed twenty-five years later.

The Greenock, built in 1848, was the first war vessel by the Scotts fitted

with the screw-propeller. We have already referred to her construction in

iron, and to her launch. She had a displacement of 1835 tons, and her

engines were of 719 indicated horse-power. The speed realised on the trial

was 9.6 knots. The Greenock's machinery, which is illustrated on the next

page, is specially interesting, as it represents one of the earliest

attempts to drive the screw-propeller by gearing. Two horizontal cylinders

were fitted, each 71 in. in diameter, with a stroke of piston of 4 ft. The

gearing consisted of four sets of massive spur-wheels and pinions, in the

ratio of 2.35 to 1, so that 42 revolutions per minute of the engines give

98.7 revolutions to the propeller- shaft. The propeller was 14 ft. in

diameter, and was so fitted that it could be detached and raised to the

deck. There were four rectangular brass-tube boilers, each with four

wet-bottomed furnaces, and all the internal uptakes united in one funnel,

which was telescopic, so that when it was lowered and the propeller raised

out of the water, the vessel had the appearance, as well as the facility,

of a sailing frigate.

As will be seen from the drawings, both the engines and boilers were

arranged very low in the hull, to be safe from the enemy's fire. The

engine and boiler compartment occupied 72 ft. of the length of the

ship—about one-third of the total length—and the seating for the machinery

was specially constructed, with a very close pitch of frames which were

only 1 ft. apart. For comparison with the drawings of the machinery in the

Greenock, we give on page 49 a similar drawing of the machinery of the

Canopus, of 12,956 tons displacement, seven times that of the Greenock. To

double the speed, the power of machinery had to be multiplied twenty

times, and yet the space occupied is only about trebled.

In 1850 the largest of the steam vessels in the Navy' had a displacement

of 3090 tons, but the most noted was the Dauntless, of 2350 tons

displacement, with engines of 1347 indicated horse-power to give a speed

of 10 knots. It is true that there were three smaller vessels of greater

speed, one of 196 tons steaming 11.9 knots; but this was the highest rate

reached in the Navy service. By this time some of the fast mail steamers

made 134 knots. These latter were suited for war service, but we have

already dealt with them.

Following the adoption of the screw-propeller in warships came the

abandonment of gearing for the engines. For many years various forms of

horizontal engine were used; first with return-connecting rods, and

subsequently with direct-acting rods. Steam pressures steadily increased,

largely owing to stronger materials being available. It was, however, not

until the 'seventies that the cylindrical boiler, the compound engine, and

the surface condenser admitted of an increase to 60 lb. per square

inch'—several years after these improvements had been introduced in the

Merchant Marine.

The Scotts had worked steadily at the solution of the problem from their

trials with the Thetis in 1858 (see page 34 ante). In 1860 the late John

Scott, C.B., laid before the Admiralty a system of water-tube boilers and

compound engines, but objection was raised to the system. The French Naval

authorities, with whom the Scotts then had close business connection, took

up the scheme, largely because of the favour with which it was viewed by

M. Dupuy de Lôme, the head of the Department. The first ship fitted was a

corvette of 650 tons displacement; the boilers worked at a pressure of 140

lb., while the initial pressure at the compound three-cylinder engines was

120 lb. These were the first engines of the compound type in the French

Navy.

The Scotts were at the time building engines for four corvettes under

construction at the Woolwich and Deptford yards for the British Navy; and

the Admiralty agreed to have fitted in one of them water-tube boilers and

engines similar to those built for the French boats. The boilers may be

said to have belonged to the same general type as the Thornycroft and

Normand water-tube steam generators. It was subsequently found impossible,

however, to ensure that the top of the boilers should be at least 1 ft.

under the load-line—a condition then enforced in steam vessels for the

Navy—and the adoption of the water-tube boiler was deferred, the ordinary

machinery of the period being fitted to work at 25-lb. pressure instead of

120-lb.

This was unfortunate, as it removed the incentive to continued research

needed to make the water-tube boiler a really satisfactory steam

generator. The Scotts, however, continued to work for the successful

application of high pressures, and it was this that brought them into

contact with the late Mr. Samson Fox, with whom they were closely

identified for many years in connection with the development of the

corrugated flue and the cylindrical steam boiler.

Opinion being adverse to the water-tube boiler, notwithstanding its

acceptance by many foreign Navies, there was a strong agitation fostered

by engineers to induce the societies for the registry of shipping, and

also the Board of Trade, to increase the ratio of the working to the test,

pressure in boilers. The British Admiralty allowed the boiler to be worked

up to within 90 lb. of the test pressure, whereas in the Merchant Service

the working pressure was limited to one-half of the test pressure. In 1888

the Scotts, being convinced that the Admiralty system afforded quite a

satisfactory factor of safety, undertook the experiment of submitting a

warship boiler, then being built by them to Admiralty specification, to

the highest possible pressure, even up to bursting-point. The boiler

ultimately leaked to such an extent, after the pressure had been

maintained for a long period at 620 lb. per square inch, that it was not

considered necessary to proceed further. The stresses at this stage worked

out to 48,130 lb. per square inch; and the result proved that there was

some justification for a reduction in the minimum scantlings of the shells

of marine boilers to, at least, the scale adopted by the Admiralty.

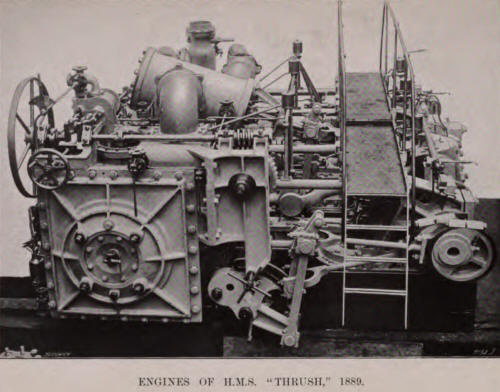

These suggestive experiments were carried out in connection with the

boilers constructed in 1888-9 for two war vessels built by the Scotts.

These vessels were the Sparrow and the Thrush. At the same time, the

Scotts engined two other vessels of the same type, constructed at the

Royal Dockyards. A view is given on Plate XVII. of the Thrush, which was

commanded by H.R.H. the Prince of Wales on the North American and West

Indian stations in 1891. She was a vessel of composite build, of 805 tons

displacement, with machinery of 1200 horse-power, to give a speed of 13

knots; but, as is shown by the illustration, she was fitted as a three-masted

schooner, and utilised her sails when the wind was favourable. In this

respect, she marks the transition stage between the days of the sailing

craft and the modern ship, depending entirely on steam for propulsion.

Indication is afl'orded of the progress towards this transformation by

Table III. on the opposite page, which shows the improvement in economy in

the machinery of warships at various stages in their development.

The figures in the Table are average results rather than highest

attainments during the periods. For 1890-95 we have taken the Barfieur,

the engines of which were constructed by the Scotts in 1894; whilst the

particulars for 1895-1900 refer to the Canopus, engined by them in 1900.

In 1902 they also supplied the machinery for the battleship Prince of

Wales, and commenced the construction of the armoured cruiser Argyll. But

before referring in detail to these latter ships, we may briefly review

the advances in applied mechanics, metallurgy and chemistry, which have

contributed largely to the perfection of these modern fighting ships in

respect of offensive and defensive qualities.

The gun most in favour at the close of the eighteenth, and at the opening

of the nineteenth, centuries was the cast-iron, smooth-bored,

muzzle-loader: first the 32-pounder and later the 68-pounder. Carronades

were used for "smashing" rather than for penetrating the skin or structure

of ships. Although the 68-pounders were improved by a lining of wrought

iron being inserted in the bore, whereby the energy at 1000-yards range

was increased from 290 to 600 foot-tons, little progress was made until

after the Crimean War, when chemists undertook the investigation of the

action of explosives and metallurgists sought to produce stronger metals.

The general idea as regards the powder used as a propellant was that the

ignition was instantaneous, and that the more violent the explosion the

greater would be the velocity of the projectile. Under such conditions

short weapons naturally found favour; and indeed, with a light, spherical,

ill-fitting projectile, there was very little advantage to be gained by

lengthening the bore. But with the introduction of rifled cannon, much

heavier and better- fitting shot became possible, and a rapid-burning

powder gave rise to dangerous pressures in the gun. It was then realised

that it was not an explosion that was wanted, but a continuous pressure

acting on the base of a shot for a relatively considerable period. This

needed a slow- burning explosive, and led to the manufacture of powder as

pebbles or prisms; the enlargement in the late 'seventies of the chamber

of the gun, and the provision of air spaces for the expansion of the

powder, greatly added to the velocity with which the shot left the gun,

and therefore augmented its carrying power.

Gun-makers had meanwhile improved the strength of the weapon by a

recognition of the fact that wrought iron was twice as strong in the

direction of the fibre as across it; and thus in the 'sixties they began

to coil the central tube, surrounding it by hoops, welded or shrunk on.

The full advantages of fibre were thus secured for resisting

circumferential strain. The bore was rifled to give the shot that rotatory

motion which prevents irregularity in flight and conduces to accuracy of

fire at long range. The smooth-bore gun was effective up to only 1000

yards range, as compared with the 6000 yards and 7000 yards for the modern

weapon. Breechloading was first introduced into the Navy in the 'sixties,

but discarded because the details for closing the breech end proved

unsatisfactory. Finally, it was reintroduced in 1878, a satisfactory

mechanism having been devised.

These various improvements gradually increased the power of the gun. The

length and weight had enormously grown, as is shown by the particulars of

successive large Naval guns, shown in Table IV. on the next page; but the

increase in energy up till the 'eighties was not commensurate with the

augmentation of the weights of the projectile and charge.

The advance from the 38-ton gun of 1870 to the 110½-ton gun in 1887

involved the multiplying by five of the charge of powder, which quadrupled

the energy of the gun, but the carrying power of the shot was still

deficient. The velocity had increased in twenty years from 1600 to 2000

ft. per second, slower-burning powder having been introduced.

Attention was further directed to the improvement of explosives; and

ultimately, instead of gunpowder having a potential energy of 480

foot-tons per pound, modified gun-cotton was introduced, with an energy of

716 foot-tons per pound, and still later there were evolved explosive

compounds of which the potential energy per unit of weight was fourfold

greater than in the case of gunpowder, namely, 1139 foot-tons per pound.

Finally, the explosive has taken the form of cordite, which ensures slow

burning, great expansion, and, consequently, augmented propelling power

behind the projectile, without material addition to the maximum strain

upon the weapon. But in any case the constructional strength of the modern

gun is enormously superior to the earlier built-up weapons, as around the

inner tubes there is coiled something like 120 miles of wire, which itself

has a breaking-strain of between 90 and 110 tons per square inch, and is

put on under a tension of from 54 tons per square inch on the inner wires

to 32 tons per square inch on the outer wires,' so that the ultimate

resistance to strain consequent upon the firing of the gun is enormously

increased. Velocities of 2600 ft. per second are thus realised, and even

more is quite feasible, so that penetration of wrought iron at 1000 yards

range has now been increased to 42 in.

If we compare the 12-in, gun to-day with the weapon of the same calibre of

twenty years ago, when there was no widened chamber for the explosive,

when prismatic powder of low expansive power was used, it is found, as

shown in the Table opposite, that the penetration at 1000 yards has been

doubled, and the possible effective range multiplied fivefold. There has

also been an enormous gain in quicker fire by improved breech mechanism

and efficient hydraulic and electric mountings, whereby the gun and all

its loading, elevating, and training machinery is rotated.

The metallurgist has also been successfully occupied, and it is probable

that the armour plate of to-day is still invulnerable. The earlier

wrought-iron plates were increased from 41 in. in thickness on the Warrior

of 1861, to the 24 in. on the Inflexible of 1881; the area protected being

almost proportionately reduced. The artillerist with improved projectiles

ultimately defeated this heavy cleading on the ships; but compound armour,

first made in 1879, enabled the maximum thickness on the broadside to be

reduced to 18 in., permitting a greater area to be covered for the same

weight. At first the 80-ton gun failed in its attack, but heavier weapons,

with improved projectiles, prevailed. The next step was the introduction

of all-steel armour in 1890. Two years later there was introduced the

super-carburising and subsequent chilling of the face of plates made of an

alloy of nickel steel. In 1897 the process of hardening was still further

developed, and now the 9-in, plate on the modern battleship is equal in

resistance to a 26-in, wrought-iron plate of the 'sixties, or a 20-in.

compound-plate of the 'eighties, or a 13-in. plate of the early-hardened

type. For the present, therefore, the armour seems to have secured the

victory, as at 5000 yards range 9-in, armour can scarcely be defeated by

even the 12-in. gun.

With the increased resistance of armour and the consequent reduction in

its thickness, the naval designer can spread his protecting plates over a

much wider area, so that the whole broadside of ships like the Prince of

Wales, or the cruisers Argyll and Defence, is clad with armour of

satisfactory resisting power. At the same time the gun-power and speed of

ships have been greatly increased without making the displacement

inordinately high. On the opposite page a Table gives the main features of

representative ships at different epochs, which will show this at a

glance.

The growth in the size of battleships has been steady, with the exception

of the class represented by the Barfleur and Canopus, both of which were

engined by the Scotts. These vessels are embodiments of a desire to check

the advance in the size and cost of the battleship. The deficiency in the

number and calibre of their guns was partly compensated by the

introduction, for the first time in battleships, of quick-firing weapons

of large calibre. The Barfleur had four 12 in. breechloaders and ten 4.7

in. quick-firers; while the Canopus had four 10 in. breechloaders and ten

6 in. quick-firers. But opinion has again strongly grown in favour of

having in each British ship the best that can be achieved; and thus the

Prince of Wales has a displacement greater than any previous ship, while

in the King Edward and the Lord Nelson classes there has been a further

growth in every element of power. The probabilities, too, are that we have

not yet by any means seen the end of this advance.

As to the machinery made by the Scotts for these battleships, the Barfleur

had three-cylinder, triple-expansion twin-screw engines, to run at 108

revolutions, and to develop 13,000 indicated horse-power. On her trials

the power was 13,163 indicated horse-power. There are eight single-ended,

return-tube, cylindrical boilers, working at 155 lb. pressure. Other

details are given in the Table on page 53.

The engines of the Canopus are illustrated on page 49 by a drawing taken

from a Paper read at the Institution of Civil Engineers, by Sir John

Durston and Admiral H. J. Oram.1 This was the first type of British

battleship fitted with water-tube boilers. She was followed soon after by

the Prince of Wales.

The Argyll, which was built and engined by the Scotts, and the Defence,

which is being built in one of the Royal Dockyards, and is having its

machinery constructed by the Scotts, signalise progress in cruiser design.

The hardening of armour, increasing its resistance, permits of a reduction

in weight for a given measure of protection, so that it has been possible

to effectively defend the modern cruiser, while at the same time giving an

enormously increased gun- power and a speed far in excess of that possible

ten years ago. The Argyll is a vessel of 10,850 tons displacement, being

450 ft. long, 68 ft. 6 in. beam, and having a draught of 25 ft.; while the

Defence is a vessel of 14,600 tons displacement, having a length of 490

ft., a beam of 74 ft. 6 in., and a draught of 26 ft. In both ships the

greater part of the broadside, from 5 ft. below the water-line to the

upper deck, is armoured, and a very large proportion of the area thus clad

has 6-in, hardened plates.

In the late 'nineties it was assumed that quick-firing artillery was best

suited to the work of a cruiser, and thus the 6-in, gun was exclusively

adopted. But since then Naval strategists have developed their ideas as to

the function of armoured cruisers, and now anticipate their use in the

line of battle; so that not only has the defensive quality been improved,

but the offensive power has been materially increased. In the Defence, and

the other ships of the class, the 6-in, gun has been entirely discarded in

favour of an installation of 9.2-in, and 7.5-in. weapons. Owing to the

perfection of the hydraulic and electric mountings, little has been

forfeited in respect of rapidity of fire, while much has been gained in

the striking energy at a given range of each projectile. Thus, while the

6-in, gun five years ago had an energy equal to penetrating 6 in. of

wrought iron at 3000 yards' range, the 7.5-in, weapon now may perforate 61

in., and the 9.2-in. gun 9 in. of the hardest armour at corresponding

range. The total weight of projectiles fired from the present-day cruiser

in a minute is double, and the muzzle energy quadruple, the results

attained by the cruisers designed at the close of the nineteenth century.

The modern cruisers steam at 23 knots, the power of the machinery in the

Argyll being 21,000 indicated horsepower, and in the Defence 27,000

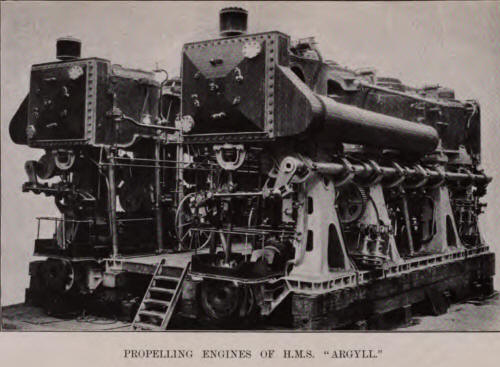

indicated horse-power. The machinery of the Argyll, which is typical,

consists of four sets of triple-expansion engines, arranged in separate

watertight compartments. The diameters of the cylinders are:

high-pressure, 44 in.; intermediate-pressure, 65- in.; and the two

low-pressure, each 73k- in., all having a stroke of 42 in. At full power,

developed with 138 revolutions, the piston speed is 966 ft. per minute.

The cylinders are fitted with liners, and are steam-jacketed; forged steel

is used for the liners of the high- and intermediate-pressure cylinders,

and cast-iron for those of the low-pressure cylinders. The cylinder covers

and pistons are of cast steel, the latter being of conical form. The high-

and intermediate-pressure cylinders have piston valves, and the

low-pressure cylinders flat valves. The cylinders are supported at the

front by eight forged-steel columns, and at the rear by four cast-iron

columns formed with guide-faces, and one forged steel column. The

crankshaft is in four pieces, the high- and intermediate-pressure parts

being interchangeable with each other, and the two low-pressure parts with

one another. The shafts are hollow, and three - bladed propellers of

manganese bronze are fitted to each.. The condensers are entirely

separate, and independent air pumps are fitted.

The Argyll had a combination of six cylindrical and sixteen water-tube

boilers, but in the later ships, including the Defence, the boilers are

entirely of the water-tube type. The working pressure of the boiler is 275

lb., reduced at the engines to 250 lb. The trials of the Argyll were

carried through most satisfactorily, and the vessel, under the new

Admiralty conditions, was completed for commission by the builders. The

fact that this armoured cruiser was so completed at the builder's yard is

of itself evidence of the capacity and efficiency of the plant.

|