arable land, which were the consequence, stimulated

that system. The increase was first mainly in the Rhins or western

district of Wigtownshire; but the Machars, which was, relatively to the

other, the richer and feeding district,

soon caught the infection of what seemed to be a more profitable

movement. On account of the contempt with which it was viewed by the

more wealthy farmers, it was with the utmost reluctance, and the regrets

usual in all caste relegations, that one after another "kept kyloes." In

Kirkcudbright the feeding caste was also strong, and as it was a

district of high class Galloway cattle, the Ayrshire cows were spoken of

as "Spotted beasts," and the owners—especially those from Ayrshire, who

were supposed to live on whey-—with no great measure of respect. By this

time a class of middlemen, also chiefly from Ayrshire, had been

developed. They were then termed "bowers," and rented the cows' produce,

thus relieving the farmer of the management. They are now, however, more

generally hired for management, and termed dairymen. It is to some of

them, who combined acquired information with careful experiment, that a

great measure of subsequent improvement is due. Mr James M'Adam had

adopted the Cheshire system, and with very considerable success, so

early as 1844, when located at Balter-son, near Newton-Stewart. At the

Highland Society's Show at Dumfries in the following year the judges

withheld a premium, which they thought his sample deserved, on the

supposition that such ripe cheese could only be of the previous year's

make; but at the Edinburgh meeting in 1848, the highest honour was

conferred. His cheese had then acquired a wide reputation, and brought l½d.

per lb. above the average price. In 1854 the Ayrshire Agricultural

Society sent a deputation to Somerset, to acquire a knowledge of the

Cheddar system, which, previously limited to a small district, was now

fast widening its reputation and its sphere. Unfortunately, the

gentlemen composing the deputation were not cheese-makers, and the

result of their labours was the appointment of a Somerset teacher—a Mr

Harding—and at a subsequent stage, a Mr Norton. In 1855, Mrs Robert

M'Adam, then in Baldoon, went to Somerset, and the improvement which

took place in the general manufacture in Galloway dates from her return,

and the lessons subsequently learned in her dairy—not that this was the

introduction of the method, for a Somerset dairymaid had first made

Cheddar near Castle-Douglas, and Mr Robert M'Adam had seen Mr Harding

discourse in Ayrshire. James had even experimented at the time he was

engaged with Cheshire, but no great standard of perfection was attained,

until the information acquired by Mrs Robert had been weighed in

continued practice and tested by successive experiments. At this time,

however, specific periods of time regulated the process, and irregular

makes were common.

The writer had, in common with the M'Adams, made fair

cheese, taking first prize at Stranraer in 1860, with Alexander M'Adam

(who was then about the best maker) in competition. But being still

dissatisfied, he went in 1862 to Somerset, and found fine dairies few ;

irregular and poor, much more numerous. A Mr Somers, near Shepton

Mallet, had the finest he saw, but this gentleman had never exhibited;

while, on the other hand, one who had acquired a reputation in the north

was 14s. per cwt. behind him in price. On returning, the improvements

noted and the experiments suggested from a well-kept register were

imparted to all and sundry; and as Robert M'Adam was similarly engaged,

a very marked advance in price bore testimony to the results of their

efforts. In 1868 the writer had due appreciation, in a presentation of

plate by twenty-five proprietors and farmers, who had profited by his

teaching. The interest taken by him in mechanical appliances, and the

construction of cheese-rooms and dairies, was well seconded by the

proprietors, and no little of the superiority of Wigtownshire to

Ayrshire and the Stewartry was due to the earlier recognition of this

department. The writer claims the introduction of steam below the tub,

between the false and true bottom, and some less notable improvements;

but he would have it clearly understood that it would be unjust to

ignore or detract from the large contribution to the Cheddar system by

the M'Adams. The Hannays, Harcomb, Sawers, Baird, Smith, and others more

or less famous are their disciples ; and the cheeses exhibited by

Alexander at Kilmarnock, if equalled, have never been excelled. Robert

has made a name in America, and his papers read at the dairy conventions

are reckoned as emanating from the best practice, and a knowledge of the

theory which leads to it. As a matter of fact, of the pupils of the

Somerset men who came north as preceptors, very few made any mark in the

show records, and none of them a very high one. In 1869 a challenge for

£200 aside, sent by the Galloway to the Somerset makers, was declined.

The general opinion among the dealers most conversant with both was,

that one or two of the best prizes would have gone to Somerset, the

greater number to Galloway.

Dunlop Characteristics.—The aim of the Dunlop

makers was to avoid acidity, consequently the evening's milk was thinly

distributed on the vessels, and the temperature kept low. In the process

much rennet and high temperature were used, and hot, not sour, whey

occasionally added. The curd was first cut into large pieces about 4

inches square, then several times, until an inch square was reached. The

remainder of the process is similar to Cheddar, which will be detailed

at full length. It is, however, to be noticed that the Dunlop maker aims

at what Dr Voelcker considers the best practice in regard to acidity,

viz., taking off the whey when it is not noticeable to the ordinary

observer; and what he erroneously sets down as absolutely neutral.

Subsequent Decline.—-That the quality of Cheddar cheese has since

1870 suffered materially is without question. It was noticed by

outsiders, and especially the dealers, but the latter were not credited

with a disinterested motive. American cheese, which had been previously

inferior, was moving in the contrary direction, and noticed both by

travellers and in the London markets. The causes of this deterioration

are—first, the reaction which almost invariably follows an abnormal

effort; second, some of the best authorities lessened their interest,

and less careful ones were only going for whatever would lessen the work

and shorten the process; third, the use of sour whey usually discouraged

by the very best makers was more and more indulged in; fourth, the sour

whey was usually kept over and in a manner to engender impure flavours;

fifth, the temperature of the evening's milk was usually too low in the

morning; sixth, too much whey was retained in the cheese on account of

weight, and also its being sooner marketable. These, briefly, are the

reasons, but it must still be noted that there were always a few whose

makes upheld the former reputation. But as the deterioration began to be

more generally acknowledged, it was resolved to make amends; and as it

was understood that there were some very fine Canadian and American

cheese sold in London, attention was turned in that direction, and

through the instrumentality of Mr Clement of Glasgow, the largest buyer

in Scotland, Mr Harris of: New York State, who had acted as factory

instructor in both Canada and New York, was engaged to instruct anew the

cheese-makers of Scotland.

Harris' Method—Difference noted.—Mr Harris

prefers having the evening's milk at 68° in the morning. When the two

meals are put together, he raises the temperature to 90° to "ripen."

There is no difference as to colouring, but the rennet is not

immediately added—only after the milk has sufficiently ripened. This is

tested by a drachm of rennet being put to a gill of milk, and when this

coagulates in twenty-five to thirty seconds, the ripening is complete,

and the milk at 88° has the rennet added. Using knives rather than

breaker, he scalds to the ordinary temperature, and no alteration occurs

until the curd is put on the rack in the cooler. He mills the curd about

halfway between leaving the tub and vatting. In cold weather he also

introduces hot water about 110° below the rack, so as to hasten the

work. There is no doubt that a better knowledge of how to handle rennet

and salt in making a cheese suitable for easy marketing or the opposite,

is due to Mr Harris.

Process Detail.—Having fixed on the system of

cheese-making to be pursued, the Cheddar being that almost universally

endorsed in Scotland, and having completed all the arrangements, it is

intended to follow the cheese-maker throughout the process from the time

the milk leaves the cow until the cheese is marketed.

The Milk itself.—Milk when drawn from the cow is

impregnated with what is known as animal odour, and if this be not

dispelled before commencing to make cheese, it will cause considerable

annoyance, and very probably a cheese of indifferent flavour. It

resembles mixed breath, and perspiration of the cow is present in

greatest proportion in the newly drawn milk, and on exposure to the air

is slowly evolved. If the milk is too quickly or too low cooled, it will

not readily escape ; if too warm, it develops as readily as before

leaving the cow ; but boiling effectually prevents its being formed.

With such complex movements the cheese-maker is at a loss how to deal

with it, but experiments made by an intelligent neighbour, in which the

writer has carefully noted the effects, bids fair to defeat the

redoubtable enemy, The milk is passed slowly over a refrigerator,

without however applying cold water or reducing the temperature

otherwise than by exposure to the air, and the results have been so

satisfactory, that Saturday evening's milk can, without injury, be put

in the Monday's cheese. Should this practice have universal adoption,

cheese-making on the Sabbath could be altogether avoided, and give

mutual satisfaction to those who have strong views on both periodical

relaxation and Sunday labour. It must, however, be observed that quick

driving of the cows, bad or stagnant water, and similar maltreatment,

will increase animal odour, and hasten the arrival of acidity, so that

it will take the best management to turn out a moderately good cheese.

It then behoves the dairy farmer or dairyman to look well to the

treatment of the cows, and along with it study, and thereby be able to

counteract, the effects of this natural flavour.

The Evening's Milk.—A knowledge of the quality of

milk is desirable, and in the absence of anything like a quick and cheap

analysis, the milk should be tested in a lactometer, so as to learn the

percentage of cream, and thus the richness of the milk, because by that

the future movements must to some extent be guided. The milk is then

placed deep or shallow in the coolers and tub according to the weather,

so that the temperature may in the morning run from 65° to 70°. If the

milk has been run over the refrigerator, it requires, of course, to be

set deeper. If then the temperature is too low, acidity is not enough

advanced; if too high, the contrary ; but, as will be noted, good

management will overcome either to some extent, and hence a study of

relative temperatures is requisite, so that at any time the maker may

readily grapple with what either hastens or retards. Steam may be used

below the tub to raise the temperature after being refrigerated, if

necessary, also cold water through the refrigerator to lower it.

The Morning's Milk-—Being over 90° when drawn, it

would be lowered by being passed over the refrigerator, and when mixed

with the other meal the average will probably be 75° to 80°.

Colouring.—The colouring, which should be the

best obtainable, is first mixed with about a gallon of milk, then with

the mass, and sharply stirred until the mixture is intimate. Some kinds

of colouring make the cheese "heavy or leady," to use a trade term, but

experience will guide fairly to a few of the best manufactures.

Ripening Tests.—The milk is now raised to the

normal temperature of 90°, varying above or below according to the

temperature and acid advance of the evening's milk. At this stage it is

absolutely necessary to have some test of the " ripening," as otherwise

the rennet may be added at a stage either too early or too late. After a

little experience, the operator will know the proper tint to which to

bring the litmus paper. Rich milk requires to be deeper than poor, so

also deeper in cold than warm weather. The writer has frequently

noticed, that although the evening's milk might in the mornings of

different days be the same temperature, nevertheless the time required

to bring the same tint on litmus paper would vary from twenty-five

minutes to an hour and a quarter. There is almost no question of the

litmus paper being superior to the sample coagulated by Mr Harris as a

test, but it must be admitted that it is so only in the hands of one who

has a good eye for colour, and who can readily distinguish the slightest

difference in shade. The paper too only serves for " ripening," not all

through the process, and thus shows the need of what was, even in the

early Cheddar days, called an acidometer. Another curious fact is

observable in the use of the paper, that it registers acidity in newly

drawn milk, not unlikely due to carbonic acid in the animal odour, but

the normal tint holds when it is evolved, and with the developing of

lactic acid, again responds. In any case the ripening depends largely on

the state of the atmosphere, and a want of knowledge of this fact, or a

due appreciation of it by the early makers, especially the pupils of the

Somerset men, was the shoal on which many a "Kane" was wrecked.

The Thermometer.—It is not so generally

considered, as might be believed, that the thermometer should be

critically tested before being used. That by which the medical faculty

tests the temperature of the human body is very generally correct, and

one should be kept for testing those which are in daily use.

Rennet.—It is very important that the rennet

should be strong and pure in flavour. For a detail of how to make such a

solution, reference may be made to a report on "Dairy Farming as pursued

in Galloway," and published in volume vii., fourth series, of the

Transactions. It has been advanced by several authorities, endorsed

by Mr Harris, that nothing will make so good curd as the calf's stomach;

bat the 2nd prize, ton lot, shown this year in London by Mr Wither of

Awhirk, near Stranraer, were "steeped" with a solution from a mineral

base. The stage of "ripening," at which the rennet should be applied, is

one to be narrowly watched, for if allowed to pass, the process has to

be quickened, and the whey will be acid before the curd is firm. If

anticipated, the process will be delayed, the curd will be too long in

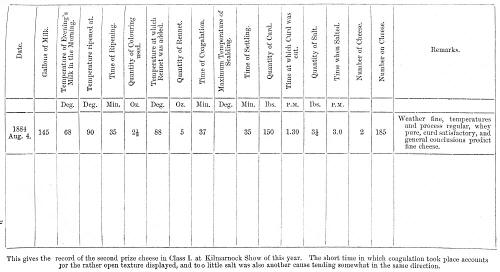

the whey, and become too hard and dry in the cheese. The register, of

which an example follows, is here of great assistance in bringing the

maker to a knowledge of the exact stage. The strength of the solution

should also be tested before using in any quantity, so that the time

required for coagulation may be uniform from fifty to sixty minutes. The

temperature may have fallen somewhat; if below 88° it should be raised

to about that point before the rennet is added.

Cream on the Milk.—After the rennet has been

added, the surface of the milk should be occasionally stirred with the

bottom of the dipper, so that the cream will be kept from coming to the

top, a tendency due to its less specific gravity than the milk,

otherwise part would escape with the whey, rather than be embraced and

fixed in the curd.

Cutting the Curd.—The milk should coagulate to a

proper firmness, and should not be cut either too early or too late, for

with the former the finer particles of curd which are suspended in the

whey, usually called "white whey," will be dissipated along with it;

with the latter, the curd cannot be got fine enough, and it will also be

toughened. Cutting intermittently afterwards, until the whey assumes a

greenish tinge, will to some extent counteract too early cutting, while

a more industrious use of the knife will have a similar effect on that

which has been too long deferred.

Heating the Curd.—The heat has at first to be

raised very gently, because the curd is at this stage very tender. If

the rise is too sudden, a glitty hard coating will form around the curd

particles, and prevent the escape of the whey, the heat from acting more

effectively, and besides, will liberate some of the butter fats, or at

least some of the essential oils, to be lost along with the whey.

Stirring after maximum Temperature is reached.-—It

is a mistake to stir too long after raising to the desired point in

scalding—98° to 102°—the effect being to prevent the finer particles

from settling, and thus allow them to go off with the whey rather than

join the main body in the bottom of the tub.

Test for running off the Whey.—The elastic state

of the curd to be desiderated, and well known to every good

cheese-maker, is easily arrived at if the milk has been of good quality,

and the acidity not too far advanced before adding the rennet; but if

the opposite has obtained, the curd will not spring out after pressure

in the hand—an indication that the cheese will not be a good one. The

cause of this want of elasticity is the curd being too moist; and to

obviate this, it should, as soon as acid is observed in the whey, be put

in the cooler. Active stirring should follow, and for a longer time than

usual, so as to get rid of as much whey as possible. And it is

noteworthy that, provided the temperature is kept up, the curd, being in

or out of the whey, has the same effect in advancing acidity. If the

curd is still too moist, increase the quantity of salt when you arrive

at that stage.

The Cooler should be of such size as will deal

comfortably with the largest quantity likely to be handled during the

season. It is just the shape of the old zinc cooler which was used for

milk, and in it is placed a sparred arrangement called a rack— about one

inch and a quarter from the bottom—through which the whey drains off

rapidly and thoroughly. A cover of canvas is required, and it should be

longer and wider by a foot than the cooler itself.

Milling and Salting.—After the whey has been well

drained off, the curd is put to the end of the cooler at a depth of a

few inches—more or less according to weather temperature—and covered for

about twenty minutes. It is then cut about 6 inches square, and turned

occasionally until ready for milling. This, as a rule, will be about an

hour and a half, or halfway between the time the curd has been put on

the cooler and that at which it is to be vatted. After milling, stir

occasionally, so as to get rid of any gas or impure flavour, at least in

some measure; but the use of the refrigerator surface, for dispelling

animal odour, would almost certainly render this in most cases

unnecessary. The stage at which to apply salt—for it stops the gathering

acidity—is a critical one, and requires a pretty accurate test to

decide. There are several, the most certain being the soft peculiar

feeling, not inaptly named "velvety" by the Americans ; equal quantities

of butter and whey exuding, on the curd being firmly squeezed in the

hand; the response to the hot iron being the flavour of nice toasted

cheese; the perception of acid by the smell; and it may be readily

inferred that any more than one will likely render a better decision.

Moisture.—The term—a very general one—does not

seem to have been clearly explained by any of either our own or American

instructors. The percentage which is desired in a ripe cheese is

composed of the water of the whey still remaining; the essential and it

may be, some of the volatile oil derived from the butter, and the butter

fats. In a skimmed milk, or very poor cheese, the proportion of whey is

large, and when it has passed its proper stage of ripeness part of it

will evaporate, and the cheese apparently lose quality, whereas it loses

moisture or water only. In a full milk or very rich cheese, the

proportion is reversed, and the moisture being from richness the cheese

will keep, nay even improve, for months or even years. Speaking

generally, a cheese with little moisture is obviously dry and hard, but

it is also slow to ripen. With too much moisture, it is soft and greasy,

and matures too soon. It taxes the skill of the operator to the utmost

to determine the proper grist all through the process, and is a test on

which to found superiority. The various markets and public taste settle

the aim, varying somewhat in different countries-—in America 27 to 30

per cent., in England 35, while the Scotch fashion runs between the

figures noted. After knowing well the market, it is possible, with a

little experience and strict attention to the rules laid down for

general guidance, to come very near the mark. If the curd is too moist,

it may be improved—

1. By using less rennet.

2. By keeping up slightly higher temperatures.

3. By breaking the curd finer before scalding.

4. By making the curd firmer before running off the whey.

5. By increasing the quantity of salt.

These, as a rule, will not be all applicable to any

one day's make, but varied both individually and in combination during

the season. The converse holds good similarly, when less moisture is

desired. What has been said may be exemplified by the,

Variations of Process at different Seasons.-—When

the cows first go to the grass the milk is comparatively poor,

consequently more rennet is used, and the means already mentioned for

increasing moisture are called into requisition. When the volume of milk

is small, it is richer, especially in spring and autumn, and those

should then be adopted which prevent excessive moisture. In cold

weather, the temperature of the dairy should be raised sufficiently by

artificial heat; and if necessary for the fret-extraction of whey, hot

water may be introduced in the cooler below the rack. When the weather

is cold and the milk small in quantity, so that the evening's milk is

too low in the morning, more or less of the milk should be kept over the

twenty-four hours. If making only on alternate days, the milk requires

to be kept at different depths—the first meal shallower and deeper as

coagulation is neared.

Appearance.—Cheese as regards appearance has its

place among the fashions. The shape being thus settled, attention should

be directed to having them all of one size, so as to present to a buyer

an even lot. Even the surface requires finish, most makers scalding the

cheese with a hot cloth so as "to sound it," i.e., give a smooth

appearance, but care must be taken not to push it to the extreme. After

being kept in the press for two days or so, neatly bandaged and removed

to the cheese room, one end is then rubbed with melted butter, the other

similarly, at the first turning on the shelves, a process which may with

benefit be repeated. In short, a good cheese should look so, therefore

the surface should be smooth and clean, and betray no irregularity in

colour.

Temperature of Cheese-room.—The ripening also

requires attention, for although an imperfect cheese cannot be made

perfect, yet a very good cheese may in this process be altered into a

middling one. The construction of the building should secure certain and

easy control of the temperature,—about 65° being the average desired;

overheating melts the butter fats and they then become rancid, and

injure the flavour of the cheese. Turning daily, and rubbing

occasionally, must not be neglected.

Quality.—A good cheese should be rich without

being greasy, and possessed of a sweet nutty flavour, as well as a clear

and equal colour. It should have a compact, solid texture, but not waxy,

and yet melt easily in the mouth.

The Register.—Still another important point

remains, for by means of the register the cheese-maker can ascertain the

requisite conditions in both milk and curd for the production of tine

cheese. The daily use of such a one as that, of which an example

follows, gives an opportunity for fixing definitely the quantity of

rennet, the different temperatures, &c. Under Remarks may be

noticed the peculiarities of weather, taints, and the probable causes ;

indeed, any point of interest to the maker, and which for reference and

comparison will serve as a compass by which to steer the future course.

Each day's cheese should be numbered, so that on examination the

conditions under which it was produced can be had from its corresponding

one on the register. By successive comparisons and tests, it is easily

seen that at length a fairly intelligent maker will achieve success, In

fact, the use of the register is indispensable if a thorough

acquaintance with the business is to be obtained. The foregoing

instructions apply to the system in which the temperatures are raised

through the use of hot whey, as well as in that where steam is

altogether used for this purpose. For "ripening" and scalding, the

temperatures are the same in both systems—for scalding, the whey being

heated to from 100° to 140°.

Present Market Status and future Improvement.—It

may readily be admitted that a decline in quality has been marked in a

large section of Scotch Cheddars—even maintained that more general

success ought to be achieved with our present knowledge. The causes of

the decline have been referred to in noticing the appointment of an

American expert; but there are others to which I will now refer. In the

first place, the person to be entrusted with making a large dairy of

cheese should be selected. Not only general intelligence—for the

exercise of which there is enough opportunity—but certain other

qualifications should guide that selection. Large power of perception,

strict attention to duty, promptness in acting on good judgment,

quickness and accuracy of the eye, the smell, and the taste, and above

all in an eminent degree the cardinal virtue of patience, will most

likely characterise the successful operator, And it is for employers to

judge how far remuneration should accord with results, the opinion of

the writer being that the salary should be regulated thereby, and thus

merit have its reward. This suggests, what has lately stirred inquiry as

regards the best mode of instruction, and there can be little question

of the wisdom of establishing dairy schools, a subject well deserving

the consideration of the Directors of the Highland Society. But like

other educational establishments, they should have their inspectors, not

only to deal with the schools, but be of service on the individual

farms, when required. And it is well worthy of the attention of farmers,

who have either small holdings or have been unsuccessful on the average,

how far the factory system, or at least associated dairying, could be

substituted. But if dairy farming is conducted as at present, then the

farmer should himself become conversant with the peculiarities of the

farm and dairy, and the management best suited to them, so that he might

be able to instruct the new hand, to whom he is to entrust this

important branch. Not only will this study prove interesting but

profitable, besides conferring a boon on the class of consumers who will

pay a good price for a good article—one widening daily, and whose demand

is more than the supply. On these grounds, all interested in dairy

produce should unite in common effort, so that, as illustrated at our

great national shows, improvement lately made should be maintained and

continued until a level is reached which, if not the highest, will at

least be abreast of that attained some twenty-five years ago. And it has

frequently occurred to the writer, that, for the smaller dairies

especially, there should be an effort made to acquire a knowledge of the

making of fancy cheese, which brings a higher price than Cheddar. A

deputation, composed of perhaps three farmers or dairymen—one of whom,

at least, could make good cheese—should put all on an intelligible

record, while the whole three being conversant with the principles and

practice adopted at present, and the variations which they would notice

abroad—could hardly fail to convey the information which would be needed

to make marketable Roquefort, Gruyere, Gorgonzola, and other fancy

cheese. As an example of what has been done in America, a friend of the

writer assures him that he found as fine Gruyere, which had been made in

Ohio, as any he had tasted in Switzerland.

Science.—The phenomena accompanying the changes

in milk are well known as regards their existence, but very

indifferently understood as to their true nature, and the means to be

exerted in controlling them. The cheese-maker, having settled in his

mind the method to be adopted, begins to study it, very probably

imperfectly, but much more likely without any study, begins to put it

into practice. He will most likely forget to consider carefully the many

details which effect the product, and follow slavishly some given

process without considering the circumstances which affect it. The

application of theory alone, without that close and intelligent

observation and attention through which successful practice can only be

attained, will end in failure more or less complete. How often do we see

all the advantages of sound instruction and good example fail to produce

anything approaching a uniformly fine make, and not less so that on one

removing to another district —it may be an adjoining farm—the change is

marked by a vast difference in the relative superiority or inferiority

of the cheese. This just shows that what might be good practice is often

the reverse for want of sufficient knowledge. But the converse is

equally true, for often the failure of those, who apparently have all

the system at their finger ends, is to be attributed to want of

observation and strict attention to detail. The question then arises,

What has science done for cheese-making ? and the answer must be, that

while in other industries development has, from this source, been very

rapid and well marked, in this one little benefit has been derived. The

application of steam, the use of the thermometer and litmus paper, come

under this category, but are not begotten of special aim. Farmers no

doubt are to blame for ridiculing science as unreliable, but the best

practice can only be founded on sound theory. And there is no doubt that

the best stage for withdrawing the whey—viz., before acidity could be

detected by any but the most minute test, but not, as Voelcker

contended, without its presence at all—should have been readily answered

at any time on the question being put to a competent chemist. Science

has even done more ultimately; it gives us the reason,, The lactic acid

which developes in the milk, through a chemical change of the milk

sugar, has the power of dissolving some of the mineral constituents—such

as the phosphates of lime, magnesia, and iron, the former having a large

representation in the ash of milk. If then acidity is too far advanced

before the whey is run off, the curd loses some of its constituents,

which, when the cheese is ripe, render it less palatable and more

indigestible. There are still a great many queries to be propounded to

science ; and it is to be hoped the answers will be so explicit as to

contribute largely to the improvement of dairy produce. The analysis of

newly drawn milk; the change in the volume, and the constitution on the

evolution of the animal odour; a minute and easily understood test of

the acidity present at the first, and the progressive stages of change,

demand attention. The constituents which may by accident of weather or

otherwise be lost, should be capable of being replaced, and it is for

the scientist to tell us how. He ought to be able to tell—-from the

composition of milk and the surrounding circumstances—what alteration of

process would be required. In short, the peculiarities of any farm could

be duly considered, if the scientific reasons were given. The Americans

have gone ahead of us in scientific investigation, and it is high time

some of the best talent should be turned in this direction.

Concluding Remarks.—In conclusion, it may be

remarked that benefit has, in several ways, been received from the

appointment of an American expert; not only in the general stimulus

given by a true appreciation of our position generally in the market,

but in the actual improvement of the process and the product. At the

same time, it cannot be denied that, with exceptional skill, a few

makers had as good cheese when made with sour whey; but it is just as

certain, that with a judicious adoption of the alterations noted in Mr

Harris' practice, more uniform success would follow. The dairy school,

and a qualified inspector, seem the only improvements likely to be

engrafted in the general system and individual effort, and there is

every likelihood that with more scientific aid, more systematic

instruction, better buildings and mechanical applicance, the average

quality will be raised.