|

Sirups for table use and

for cooking purposes may be made in the kitchen or in a small way on the

farm with the materials found at hand or constructed at small expense.

Usually, these home made sirups will not be as light colored as the

factory made products but will be of pleasing flavor, if carefully

prepared. Grapes and apples are especially well suited to the

manufacture of sirups. Sorghum is also excellent. The general principles

of sirup manufacture will be found in Chapter VIII.

(51) Fruit Sirups for

Cooking Purposes.

1. Crush the fruit and

press out the juice. Apples and berries may be heated to boiling after

crushing to facilitate extraction of the juice.

2. Heat the pressed juice

to boiling and filter through a jelly bag or other form of filter until

clear. The juice may also be clarified by methods described in Recipe

50. This will give a clearer and more attractive sirup.

3. Boil the juice down

rapidly in a shallow pan. Long boiling causes the sirup to be dark

colored and of poor flavor. The hot sirup should finally test 63%

Balling or 35° Baumé or must be boiled until it becomes of the desired

consistency.

4. Pack the sirup boiling

hot into scalded jars or bottles and seal at once. Sirup that tests 63°

Balling hot or 68° Balling cold will keep without packing hot in scalded

jars or bottles. The sugar test is not necessary if the sirup is sealed

hot.

Sirups made as above are

suitable for use in mincemeat etc., but are somewhat too sour for table

use. Grapes and apples are the most suitable fruits for this purpose.

(52) Fruit Sirups for

Table Use.

1. Clarify the fruit

juice. To do this, heat to boiling and strain till clear or clarify

according to Recipe 50.

2. Divide into two lots

representing 1/4 and 3/4 of the juice respectively.

3. To 3/4 of the juice

add 2 oz. (3 tablespoonfuls) of precipitated chalk per gallon. Heat to

boiling and allow to stand overnight. Filter through a jelly bag to

remove the chalk. The juice may also be treated with baking soda instead

of chalk. Add the soda in small amounts until there is no longer any

acid taste. Do not add too much soda.

4. To the filtered juice

add the 1/4 of untreated juice. Boil the juice down to a sirup and seal

boiling hot in bottles or jars. This sirup is less acid than that made

by the preceding recipe and can be used on griddle cakes, etc.

Precipitated chalk may be

bought from any drug store. Ground limestone may also be used. It is

harmless.

(53) Fruit Sirups by

Sun Evaporation. (See Chap. VIII, par. 35.)

1. Crush the fruit, press

out the juice and strain or filter it until clear.

2. Place the juice in a

shallow pan or make a shallow wooden water-tight trough. Place whole

apparatus in a sunny place. Hang from a clothesline or other support

above the container several strips of cheesecloth. (See Fig. 29 for

diagram of such an arrangement.) Dip the cloths in the juice and hang

them above the pan or trough. In a few minutes the juice will dry to a

sirup on the cloth. Dip them in the juice; wring out the sirup into the

juice; dip again and hang up to dry. Repeat this until the sirup reaches

65% to 68% Balling or 35% to 37% Baumé. (See Chap. II, par. 11, for use

of these testers.) Store in bottles or jars.

This sirup will have a

great (leal of the fresh fruit flavor and may be diluted as a beverage

or may he used in cooking. Sirups for table use may he made in a similar

way by modifying Recipe 52 accordingly.

(54) Fruit Sirups made

by the Addition of Sugar.

Highly flavored and tart

juices may often be sweetened with sugar to give heavy sirups suitable

for use in soda fountains or as bases for home made beverages.

1. Lemon, Orange and

Grape Fruit Sirups. Grate off the oil cells from 1/2 doz. fruits. To the

gratings add 2 1/2 lbs. of sugar and 1 pint of the juice of the fruit

used. Warm until sugar dissolves. Stir and allow to stand with

occasional stirring for three or four days. Press through a cloth to

remove gratings.

2. Pomegranate, red grape

juice, strawberry, loganberry, raspberry, and blackberry juices may be

made by adding 1 3/4 lbs. sugar to each pint of juice. This sirup will

keep without sterilization.

(55) a. Sorghum Sirup.

Home Recipe.

1. Crush the green sugar

sorghum canes. A food chopper may be used for small scale work; for

larger scale work a cane mill will be needed. The ground cane may be

boiled with a small amount of water and pressed a second time.

2. Heat the juice to

boiling and strain until clear.

3. Boil down until the

sirup will test 63% hot or 68% Balling cold, or until of desired

consistency. Seal hot in scalded jars, bottles, or cans.

(55) b. Manufacture of

Sorghum on Small Commercial Scale.

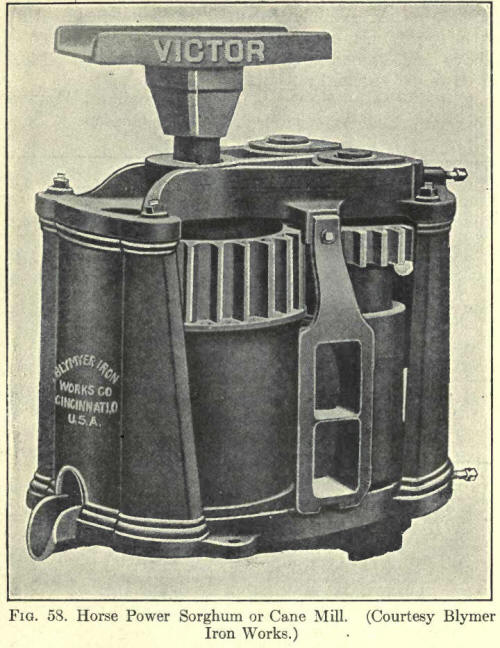

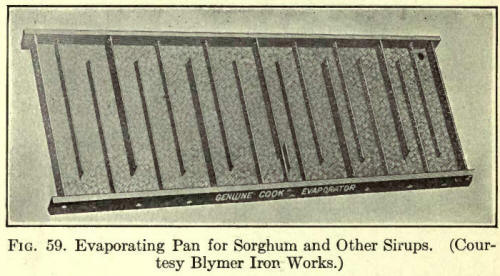

1. Equipment. Small horse

power mill (see Fig.); galvanized iron or copper evaporating pan 8 to 10

ft. long (see Fig.); portable furnace for pan; settling pan at crusher

about 6 to 8 ft. long to permit settling of juice (this pan may be made

of galvanized iron to receive juice at upper end of pan and to allow

settled juice to flow out at lower end into a settling tank); settling

tank or barrel of 50 gals. capacity for fresh juice; two open 50 gal.

barrels; skimmer for use during boiling of sirup; 10 or 15 gal. open

barrels or tubs with spigot, to be placed above and at one end of

evaporating pan to supply juice to pan; several buckets and dippers.

2. Varieties of Sorghum..

Honey Sorghum, Orange Sorghum, Red Amber Sorghum, and Gooseneck Sorghum

are all good varieties. Plant quick maturing varieties in Eastern states

and late maturing varieties in California.

3. Harvesting. Strip off

leaves from canes when seed is almost ripe; cut canes at 6 to 8 inches

from ground. Cut off seed heads and haul stripped cane to the mill at

once. Leaves and seed heads spoil the flavor of sirup and make it hard

to clear, therefore, they should be used for forage only and not for

sirup.

4. Press juice from

stripped cane by running it through a sorghum mill (see Fig.). The mill

is set on supports so that bottom of rollers is about 40 inches from the

ground and is operated by a sweep fastened to top of rollers and drawn

by one or two horses. Power mills may be used for larger factories.

5. Allow juice from mill

to flow continuously through settling pan and from settling pan into a

50 gal. settling tank.

6. Heat to boiling and

allow to settle 4 or 5 hours in settling tank. This can be done by

running the juice through the pan at such a rate that it will be heated

to boiling but not concentrated to a sirup. Skim off floating material

and draw settled juice off from sediment. The settled juice is used for

sirup; the sediment may be used for stock feed or strained and used for

sirup.

7. Fill the evaporating

pan with the juice and boil down to a sirup. Allow sirup to flow from

the pan and the juice to flow into the pan at such a rate that the sirup

tests when hot, 36° to 40° Baumé or 65° to 73° Balling or Brix. A very

hot fire is essential; quick burning wood is best; crude oil can be used

if a special burner is installed.

8. Allow sirup to settle

4 or 5 hours in a shallow vessel. Draw it off and fill into sirup cans

or kegs.

Sorghum sirup outfits may

be obtained from dealers in farm machinery. (See par. 12, and par. 46,

for description of sugar and sirup testers.)

(56) Sugar Beet Sirup.

1. Wash and cut in thin

slices. The thinner the slices the better.

2. Place slices in a pot

and barely cover with water. Bring to the simmering point or to 175° to

180° F. and keep at this temperature about 45 min. Strain off the hot

sugary liquid through a cheesecloth. It is not necessary to press the

beets. A second more dilute juice can be obtained by heating the slices

with fresh water.

3. Strain the juice till

fairly clear. Boil down rapidly to a heavy sirup and skim off material

that comes to the surface. Seal hot in scalded jars, bottles, or cans.

This sirup will be dark colored but is suitable for some forms of

cooking and for table use. |