|

There are many lines of steam vessels now sailing

from the Clyde to various parts of the world.

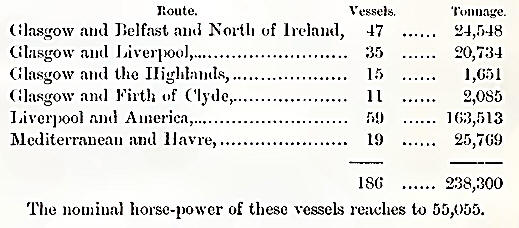

The total number of ships which have carried the flag

of the old Arm of G. & J. Burns, started in 1824, together with that

in the new Cunard Co., started in 1840, reaches to 180 vessels,

divided as follows:—

The years in which these various routes were started

are: Glasgow and Belfast, 1824; Glasgow and Liverpool, 1828; Glasgow

and the Highlands, 1832; Liverpool and America, 1840; Glasgow and

the Firth of Clyde, 1840; Liverpool and the Mediterranean, 1853.

As it is interesting to know something of the origin

of such widely-spreading and successful undertakings, so is it also

desirable to have some idea of what the first vessels were like with

which the various routes were opened. The first steamer on the

Glasgow and Belfast route belonging to Messrs. G. & J. Burns was

the Finyal, a wooden paddle steamer of 290 tons and 100 horse-power.

The powerful steamers for the Belfast service, built and

engined for the firm by Messrs Barclay, Curie, & Co.

a few years ago, measure 250 feet in length by 30 feet in breadth

and 14 feet 7 inches deep. The speed is 15 knots, the average

passage from Greenock to Belfast being 7 hours. Between Glasgow and

Liverpool there was the Glasgow, a wooden paddle steamer of 280 tons

and 100 horse-power, built by John Wood, Port-Glasgow, engined by

Caird & Co., Greenock, with side-lever engines, the steam pressure

being only 5 lbs. per square inch. Plying between Glasgow and the

Highlands was the Stuff'a, a wooden paddle steamer of 60 tons and 45

horse-power, and between Liverpool and New York, the Britannia, a

wooden paddle steamer of 1154 tons and 440 horse-power. This early

ocean steamer was only 207 feet long (about the length of an

ordinary Clyde passenger steamer of the present day), 34 feet broad,

and 22 feet deep, fitted with side-lever engines. Her speed was

about 8 J knots. Sailing between Glasgow and the coast, the Dunoon

Castle, a wooden paddle steamer of 190 tons and 50 horse-power; and

between Liverpool and the Mediterranean ports, the Taurus, an iron

screw steamer of 1126 tons and 180 horse-power (nominal).

The Britannia was built at Greenock in 1840 by R. Duncan and Co.;

the engines were by R. Napier. The dimensions were: length, 207

feet; breadth, 34 feet; depth, 22 feet; gross tonnage, 1155. There

were two side-lever engines, the diameter of the cylinders being 72

inches, with a stroke of 6 feet 10 inches. The power was 403

nominal, and the speed about 81 knots. The Persia was built in 1856

for the Cunard Co. by R. Napier & Sons at Glasgow. Dimensions:

Lengtlq 375 feet; breadth, 46 feet; tonnage, 3590; 850 nominal

horse-power, or about 3600 actual; side-lever

engines; speed, about 13 knots, and time of passage between

Liverpool and New York, 104 days; coal burned per day, 150 tons.

The Scotia, built in 1862, was the last large paddle steamer

belonging to this company.

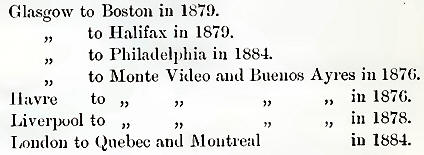

The “Allan Line,” now possessing a large and

well-appointed fleet of Atlantic steamers, may be said to have

originated three-quarters of a century ago, when the founder of the

line, Alexander Allan, owned and commanded a ship carrying stores to

the Peninsula during the old wars. Afterwards he traded regularly

between the Clyde and Canada. In 1820 the Allan Line of sailing

ships was established, and thus formed that link between the

Scottish river and that other great river the St. Lawrence which has

been continued unbroken to the present day. In 1853 the first

steamer of this line, the Canadian, was built at Dumbarton by

Messrs. Denny, the dimensions being: length, 277 feet; breadth, 33

feet 8 inches; depth, 23 feet 9 inches; tonnage, 1765. The Canadian

mail service was begun in the same year, the vessels sailing from

Liverpool. The steam service between Glasgow, Quebec, and Montreal

was started in 1862. In 1871 the company ran vessels between

Liverpool ami St. John’s, Newfoundland, Halifax, and Baltimore.

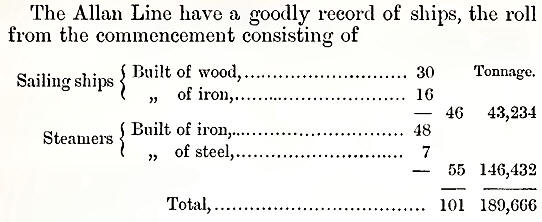

These vessels, representing as they do an investment

of about four millions sterling, will convey some idea of the

importance of this company. In the year 1881 the Parisian was added

to the fleet, built and engined by Messrs. R. Napier & Sons. This

vessel is of steel, her dimensions being: length, 440 feet; breadth,

4(3 feet; depth, 33 feet; tonnage, 536G. The first steel steamer of

this line, the Buenos Ayrean, was built in 1879 by Messrs. Denny of

Dumbarton, 4004 tons register. This vessel indeed was the first

large ocean-going steamer built of steel, which, as a comparatively

new material for shipbuilding, had still to prove its reliability

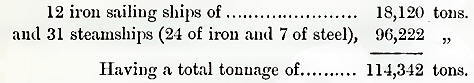

and efficiency. At the present time (1887) the Allan Line fleet

consists of

The collective nominal horse-power of the steam fleet

is about 12,530, or equivalent in these days of great pressure and

high piston speed to about 50,000 indicated horse-power.

The Anchor Line was started in 185G by Messrs.

Handyside & Henderson of Glasgow, the Mediterranean being their

first special field. In 1863, however, they commenced the Glasgow

and New York service, the Caledonia and Britannia being their first

steamers on this route; and since then their flag, with its emblem

of hope emblazoned, has waved from many a tall mast in their fleet,

their right to their adopted motto, “Secure amid perils,” having

been well-earned through the safe and efficient service which they

have now established on the ocean. The Mediterranean trade commenced

in 1854 with the Vasco de Gama, bringing from the sunny shores of

the great inland sea oranges, raisins, lemons, &c. The Atlantic

service commenced in 1857 with the Tempest, 844 tons. The Indian

service commenced in 1875 with the Cidcdonia, of 2145 tons.

Besides owning a fleet of steamers, the firm carry on

extensive ship-building and engineering works at Glasgow.

Since its commencement the company has had close on

100 vessels, having a collective tonnage of 159,000 tons.

Forty-three of these comprise the existing fleet, with a total

tonnage of 117,000 tons. Of these the Fnrnessia is the largest

vessel sailing from the Clyde, being 445 feet in length by 44 feet

beam, and 34 feet deep; tonnage, 5494 tons.

The building of sailing ships still continues to be

carried on to a large extent notwithstanding the progress of steam;

and one can frequently see some great “four master” getting fitted

with hollow iron masts, wire-rope standing rigging and running

tackle, with yards and sails, double topsails, and what not.

The sailing ship, both as a line packet ancl a China

clipper, is largely a thing of the past; but still the demand for

sailing vessels for certain routes continues. The races of the old

China clippers were exciting events, these vessels often leaving

with their cargoes of tea about the same time, and thereafter

traversing the many thousand miles of their course, only again

sighting each other as they approached the English Channel. As many

famous ships of this class were built on the Clyde, and owned by

merchants there, it may be of interest to state that the Sir

Lancelot, which was built by Messrs. Steele at Greenock, and owned

there by Mr. John MacCunn, made the passage in 18G9 from Foochow to

London in 89 days, averaging, during many days, fully 300 miles per

day.

Mr. Thomas Gray, C.B., of the Board of Trade, in an

interesting address on the maritime legislation of the last fifty

years, delivered before the members of the Shipwrights’ Company,

London, gives a number of interesting details, some of which may not

be unfitly referred to in a work on the river Clyde, more especially

as he refers to that river several times in the course of his

remarks. Speaking of the great development of the shipping interest,

he says: “In 1836 there were 25,820 ships on the register of British

ships, and their tonnage was 2,792,646 tons. Of these ships 600 were

steamers of 67,969 tons.” “In 1886 there were 38,335 ships on the

register of British ships, and their tonnage was 9,323,615 tons. Of

these ships 8913 were steamers of 4,293,115 tons. Comparing the

effective tonnage by assuming that one steam ton does four times the

work of one sailing ton, Mr. Gray concludes “that while in 1836

(taking the work done by a sailing ton as the unit) there were

2,996,553 effective tons of shipping, there were in 1886 22,202,960

tons.” In speaking of our ships, lie says: “Before 1836 British

ships were chiefly built of wood, and were chiefly sailing ships;

and naval architecture had received no adequate attention in this

country, the tonnage law being much to blame for this; but since the

tonnage law of 1854 was passed, and the improvements effected by the

skill of naval architects, and classification, the models of ships

have now been brought to much perfection.”

In speaking of seamen, Mr. Gray, says: “British

seamen are now divided into five distinct classes, and the division

between men in each of those classes is broadening and becoming

marked every day. Now the navy trains its own men, and is the most

popular branch of the national services.” Fishermen have now become

a separate class. Firemen, stokers, &c., form the third; the fourth

is the British mercantile Jack; the fifth Asiatics and others, but

British subjects. Mr. Gray does not recognize the foreign seamen as

a separate class. The naval reserve numbers

18,000 men, nearly the half of whom are fishermen.

Mr. Gray, in speaking of the improvement in our seaman, says: “ I

have to put this to his credit, that he deposits in the savings-bank

at the rate of £70,000 a year.”

THE SITUATION FIFTY YEARS AGO.

As regards 1836 I must ask you to picture to

yourselves a time of which the records are as follows, viz.:—

When British ships were classed by Lloyd’s solely on

age, or according to port of building:

When protection of British shipping existed as

against foreign ships, and when British Colonial ships were excluded

from many foreign ports, and others were admitted only on paying

a surtax de pavilion: When British ships were so faulty in design,

and as sailers so slow, that British shipowners feared free-trade,

because they knew that successful competition on equal terms with

foreign ships was impossible:

When trading harbours were so shallow that the

bottoms of ships needed to be specially constructed to take the

ground:

When, in spite of the fact that some of the officers

of the larger foreign-going ships were gentlemen of the highest

attainments and of undoubted reputation, drunkenness and

incompetency among the ordinary run of officers, as well as of

seamen, was notorious:

When charts were notoriously inefficient:

When lifeboat aud rocket apparatus were not stationed

around ou | coasts:

When the mercantile marine largely depended for a

supply of seamen on pauper apprentices:

When there was no examiuation of masters, mates, Bud

engineers: When numerous lighthouses were the property of, or leased

to, individuals for their personal benefit, and when surplus light

dues went to so-called charitable purposes, and to other purposes

unconnected with shipping:

When harbour dues, town dues, charity dues, and

passing dues were levied on ships, and were also frequently

appropriated to many purposes not solely connected with shipping:

When there were no harbours which would now be called

harbours of refuge, though a passing toll had to be paid by all

ships passing Whitby, Bridlington, Dover, or Ramsgate:

When there were scarcely any docks:

When the Clyde, Tyne, and Tees were navigable only by

small vessels even at high water, and many other ports now

flourishing scarcely existed:

When freight was the mother of wages:

When payment for salvage of life was unkuown:

When ships did not carry side-lights:

When there was no international rule of the road at

sea:

When no reports of wrecks were required to be made:

When no inquiries as to wrecks were held:

When the press-gang was in full work:

When crimps preyed, and preyed unchecked, on British

seamen: When there were no savings-banks nor seamen’s money order

system:

When there was no system for recovering the wages and

effects of deceased seamen:

When the only seamen available for augmenting the

navy in emergency consisted of undrilled men of the mercantile

marine: When there was no statutory provision as to the supply of

food or as to the accommodation of seamen:

When there were no checks to the tyranny of masters

and mates at sea; no provision for the proper execution and

enforcement of contracts between masters and seamen: no naval

courts, &c.:

When one ship was not required to stand by another

ship after collision:

When a seaman could not raise any question as to the

unseaworthiness of his ship, but could be sent to prison as a

deserter if he went ashore to complain:

When there was no international or commercial code of

signals:

It is possible that but few shipowners of the present

day, especially those who now feel inclined to complain of what they

are pleased to call “government coddling” of seamen, can bring

themselves to realize such a state of things—it is within the range

of possibility that some of them never even heard of it. Yet that

was the state of things fifty years ago, and these were the features

of the so-called “good old times” whose departure, especially as

regards seamen, they profess to deplore.

The following advertisements of some of the early

steamers are taken from a sketch of the history of the Anchor Line,

published in 1872. In connection with these early records it may be

observed that the present year has a special significance in

connection with the use of steam as a means of propulsion, as it is

just one hundred years since Patrick Miller’s experiments were made

on Dalswinton Loch. Again, it is just fifty years since the first

steam-vessel crossed from this country to America. The year 1888 is

therefore the centenary of steam propulsion, and the jubilee of

ocean navigation by steam-ships. As early, however, as 1819, a

vessel called the Savannah was built in New York. She was of 800

tons burden, ship-rigged (three masts); had one inclined

direct-acting engine; cylinder, 40 inches diameter; G-feet stroke;

20 lbs. steam; paddles of wrought iron, without paddle-boxes, and

which, it is said, could be removed and shipped on deck In about 20

minutes. She sailed from New York to Savannah on 28th March, 1819.

The following advertisement appeared in a paper of the time,

notifying her return voyage to New York:—

“PASSAGE TO NEW YORK.

“The steam-shfl Savannah, Captain Rogers, will make

one trip to New York, previous to her departure for Liverpool,

should a sufficient number of passengers offer, and will be ready to

proceed in the course of this week or commencement of the next.

Apply on board at Taylor’s Wharf, or to Scarbrough & M'Kinne.”

The following advertismcnt appeared on the 19th May,

1819, intimating her voyage to Liverpool:—

“FOR LIVERPOOL.

“The steam-ship Sar<mnah, Captain Rogers, will,

without fail, proceed for Liverpool direct, to-morrow, 20th inst.

Passengers, if any offer, can be well accommodated. Apply on board.”

Apparently the public of those days had no confidence

in this new and untried method of propulsion, as no passengers came

forward. The vessel, however, set sail for Liverpool on the 20th

May, and arrived at that port on 20th June. The engine was worked

for 18 days of the passage; pitch-pine was used instead of coal.

The Savannah then boldly set sail for St. Petersburg, and returned

to her native American shore again all safe after a successful

voyage of 50 days from St. Petersburg.

Some time after her return the machinery was taken

out, and as a sailing vessel only she traded on the American coast,

until lost in a storm on Long Island.

In 1825, The Enterprise, of 500 tons, and 120

horsepower, made the passage' to India. The Enterprise was built on

the Thames by Messrs. Gordons & Co., and launched on 22d January,

1825. She had two engines of 00 horse-power each made by Henry

Maudslay. After a long and troublesome passage round the Cape of

Good Hope, as the Suez Canal was not even thought of in those days,

she reached Madras, having had to depend on her sail power for a

considerable part of the passage.

The Sirius was built by Mr. Menzies of Leith, the

engines and boilers being made by Mr. T. Wingate of Glasgow. The

dimensions of this vessel were as follows: length, 178 feet 4

inches; beam, 25 feet 8 inches; depth, 18 feet 3 inches; register

tonnage, 412. There were two side-lever engines of 270 horse-power;

and as a notable feature in these early days, she had a

surface-condenser. The cylinders were GO inches diameter with a

G-foot stroke. The paddle-wheels were 24 feet 1 inch in diameter,

having 22 boats, each 9 feet G inches long by 2 feet G inches broad.

The Sirius left Cork for New York on 5th April, 1838, and arrived

after a passage of 181 days.

The advertisement of her return voyage reads as

follows :

“British Steam-packet Ship for London, to sail from

New York, May 1, 1838.

“The New and Powerful Steam-ship Sirius, 700 Tons

Burthen and 320 Horse-Power, Lieutenant R. Roberts, Commander,

“Is intended to sail from London, March 28th,

touching at Cork, and thence, on 2nd of April, for this port,

returning from New York to London on the 1st of May. This vessel has

superior accommodation, and is fitted with separate cabins for the

accommodation of families, to whom every possible attention will be

given. Cabin, $140, including provisions, wines, &c. Second cabin,

$80, including provisions. This superior steam-ship has been

chartered by the directors of the British and American Steam

Navigation Company, of London, to meet the pressing demands of the

public, in anticipation of the steam-ship British Queen, now

building,—is a new vessel, about six months old, and has proved

herself superior to any steam-vessel in British waters in speed and

seaworthy qualities. Further information afforded on application;

and, for freight and passage, apply to Wadsworth & Smith, 4 Jones

Lane (rear 103 Front Street), agents of the British and American

Steam Navigation Company.”

The Great Western was built by Mr. Paterson of

Bristol, and engined by Maudslay of London. She was 212 feet in

length, and had engines of 440 horse-power. This vessel left Bristol

on the 8th of April, arriving in New York after a passage of 141-

days. The Sirius arrived at New York on the morning of the 23d of

April, and the Great Western on the afternoon of the same day. The

arrival of these vessels caused great excitement in New York.

The Great Western Steamship Company afterwards added

the Great Britain. The British Queen was built at London and engined

by Robert Napier. She left Portsmouth on 12th July, 1839, and

arrived at New York after a passage of nearly 15 days.

The President, a later steamer, on her return voyage from New York

to Liverpool in 1841, was never afterwards heard of. The Royal

William was the first steamer to cross the Atlantic from Liverpool.

She was 617 tons burthen and 276 horse-power. She sailed for New

York on 5th Jnly, 1838, arriving 19 days later, and returned on the

4th August of the same year. The following announcement being made

in the New York papers:—

“British Steam-ship, lloyal William, 617 Tons.

Captain Swaiu-son, B.N., Commander.

“This fine steamer, having lately arrived, will be

dispatched again for Liverpool on Saturday, 4th August, at 4 p.m.

She is only 16 months old, and from her peculiar construction, being

divided into five sections, each water-tight, she is considered one

of the safest boats in England. Her accommodations are capacious and

well arranged for comfort. The price of passage is fixed at $140,

for which wines and stores of all kinds will be furnished. Letters

will be taken at the rate of 25 cents for the single sheet, and in

proportion for larger ones, or one dollar per ounce weight.

“For further particulars, apply to Abraham Bell

& Co.; or, Jacob Harvey, 28 Pine Street.”

A vessel also named the Royal William was built at

Three Rivers, near Quebec, in 1831. She was 160 feet long by 44 feet

broad, and 17 feet 9 inches deep, and of 363 tons register. She

crossed to Liverpool in 1833, and was afterwards sold to the Spanish

government for a war vessel, and said to be the first steam-vessel

so employed. Great changes in the forms and dimensions of

steam-vessels have taken place during the period of now fully three

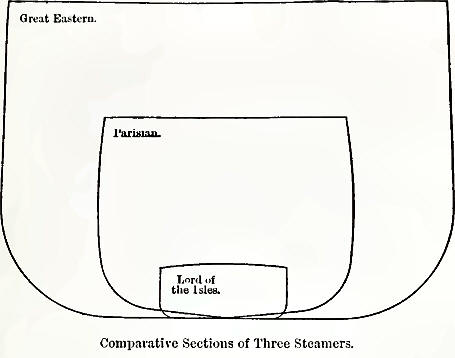

quarters of a century since the Comet was launched. The annexed

diagram shows the comparative sizes of some of the leading steamers

of this period. The Great Eastern, although now nearly approached in

length Ly the Atlantic liners of the present day, is still a long

way in excess of these in tonnage room, and displacement. The

annexed diagram shows the comparative midship sections of the Great

Eastern, a 5000-ton steamer, and a river steamer.

The ship-building industry of the Clyde is naturally

of older date on the lower reaches of the river, as until somewhat

recent times the Clyde from Glasgow for many miles down was too

shallow to admit of the passage of vessels of large dimensions.

It appears1 that the first square-rigged vessel, a

brig built at Greenock, was launched in 1760. In the year 1776 the

largest vessel built there was only 77 tons. There were larger

vessels, however, than this frequenting the harbour of Greenock,

some being of 250 tons. These, however, were chiefly built in the

colonies, and were owned in Glasgow. A stimulus, however, was given

to the Greenock building trade, both from the demands for larger

vessels and from the fact that the American colonial vessels,

although cheaper than those made at home, were deficient in

durability.

The introduction of steam as a propelling power, in

the beginning of the present century, gave a great stimulus to Clyde

ship-building, and by degrees the river banks have had yard after

yard added, until at the present time, from the lower part of the

Glasgow harbour, the building yards are met with on each side

extending for several miles, and thereafter at Paisley, Bowling,

Dumbarton, Port-Glasgow, and Greenock. Again, along the shores of

the Firth there are other ship-building yards, amongst which may be

noted the old yacht-building centre at Fairlie.

Several of the ship-building firms on the river have

existed under the same names or with slight variations during a long

period of years, that of Barclay, Curie, & Co. being apparently the

oldest—the business having been commenced at Stobcross in 1822.

Iron and steel has now replaced wood for the

construction of large vessels. The tonnage launched on the Clyde in

1864 was 178,505 tons, and in 1883 404,383 tons. Since this latter

date the general depression of trade has largely affected the

ship-building industry both here and elsewhere.

The following extract from Barkers Trade and Finance

Journal shows very clearly the relations of the shipbuilding trade

at home and abroad:—

“It is satisfactory to know that in ship-building the

United Kingdom continues to maintain a supremacy which is

unquestioned. We do sometimes hear of foreign competition in this as

in other branches of business, but the marvel is that we are able to

keep such an enormous lead as we do. The facts are astounding. Out

of a total of 404,016 tons registered by the United Kingdom, France,

Germany, Italy, Norway, and Sweden, during the year 1886-7, 327,743

tons were built in the United Kingdom and 76,273 tons were built

elsewhere; but out of these 76,273 tons no less than 19,916 tons

were wood or composite, leaving only 56,357 tons of iron or steel

vessels built out of, as against 327,743 built in, the United

Kingdom. Germany and France are the only countries which produce any

appreciable quantity of iron or steel tonnage, although Sweden and

Norway produce what little they require for their own use. Germany

is fast becoming a ship-building country, already producing

two-thirds of her fairly large requirements; and France produces

less than two-thirds of her requirements, although these are less

than one-third of Germany. No country in the world, excepting the

United Kingdom, is at present able to supply a market outside of

itself. Therefore, with the exception of the four countries named,

the whole world is dependent upon the ship-building yards of this

country for its fleets. We have only been able to maintain this

supremacy by keeping well to the front in all improvements. To the

enterprise and business ability of its ship-owners and ship-builders

this country owes much. There does not appear to be any likelihood

that they will lag behind in the future. One illustration will show

how they are taking the lead now. In the building of ships, as in

many other directions where iron has been largely used, the merits

of steel, as compared with iron, is one of the most important

questions of the day, and is being undoubtedly settled in favour of

steel. Figures clearly show that we are not slow to adopt

improvements, but rather that we are much more ready than the rest

of the world to do so. While we have practically leased the building

of wood and composite vessels, more than one-half of the total built

elsewhere are still of these obsolete types, and iron vessels are

nearly as two to one of steel, whereas we are building considerably

more of steel than of iron.”

Ship-building, like marine engineering, has now

become a science as well as an art, and one of the recent chairs

founded in Glasgow University is for the study of the principles on

which these important branches of our industrial activity depends.

The naval architect deals with such matters as form and stability,

and is conversant with such terms as metacentres, centres of

buoyancy, moments of stability, &c. The ship-builder, whether

working in wood, iron, or steel, has a definite series of practical

considerations before his mind both of a constructive and commercial

character from the time the keel is laid till the launching of the

vessel.

In the building yards in the old days of the “wooden

walls,”

“Covering many a rood of ground,

Lay the timber piled around;

Timber of chestnut, and elm, and oak,

And scattered here and there, with these,

The knarred and crooked cedar knees.”

Now in our great building yards it is iron and steel

frames and plates which cover the ground, and the sound of the “

busy hammers closing rivets up ” is heard on all sides.

The following are some of the leading steps in the

building of an iron or steel ship:—

1st. General design, including tonnage, speed, engine

power, draught of water, stability, &c.

2d. The keel. Logs are laid along the ground, and on

these blocks are placed at an inclination of about one in twenty

towards the water. The keel is laid along these blocks.

3d. The frames are composed of angle iron or steel.

They are bent to the required curves and riveted together, so as to

form a Z section.

4th. The beams for supporting the decks are formed

of T section, iron or steel. The frames are now put into place on

the keel, and the beams attached to them. The frames are then “

faired ” and the keelsons fitted.

5th. The plating is now put on, each plate being cut

to the proper size, and the rivet holes made. It is rolled so as to

fit the shape of the part of the vessel it is to occupy. It is then

taken to the ship, and riveting begins. The butts and edges of the

plating are then caulked water-tight by forcing the one edge close

to the other. The internal fittings arc in the meantime being

carried on.

But although it is of first importance that the

various building operations shall be successfully carried out, yet

unless suitable provision be made for getting the completed vessel

into the water the labour would be thrown away, or, as in the case

of the launching of the Great Eastern, a long period of time might

elapse and expense be incurred before this was accomplished. The

launching of a ship, especially of such vessels as are now built for

our ocean lines, is therefore a matter of great importance, and has

to be carefully considered. Generally speaking the various steps are

as follows: The vessel having been built resting on the keel-blocks,

ways are laid down on each side, and a timber structure called a

cradle formed around the under part of the vessel. The cradle rests

on the ways. The ways are inclined with slopes varying according to

circumstances.

Prior to the launch these ways arc coated with

grease, and the cradle allowed to rest upon them; the keel-blocks

are then removed, and the vessel allowed to rest completely on the

cradle, the latter being kept from sliding downwards by a movable

piece of wood called a dagger, which is knocked out of its place by

a heavy weight allowed to fall at the moment of launching by the

cutting of a cord, usually assigned to a lady visitor.

Besides the harbour and dock works at Glasgow already

referred to, there are other public and private docks on the line of

the river, sneli as at Bowling, Dumbarton, Port-Glasgow, and

Greenock.

The harbour works at Greenock are now distinguished

as the old and new works.

The West Harbour, commenced 1707, has a water area

of 7b acres, with a public graving-dock 220 ft. long, with about 10

ft. depth on sill. The East India Harbour, commenced 1805, water

area 6½ acres. A public graving-dock is connected with this harbour,

356 ft. in length, depth on sill about 12 ft. The Victoria Harbour,

commenced in 1846, water area 5½ acres, length 560 ft., width of

entrance 150 ft., depth at low water 14 ft. The Albert Harbour,

commenced 1862, water area lOf acres, length 1000 ft., width of

entrance 100 ft., depth at low water 14 ft. In the construction of

the Albert Harbour a new system of working without coffer-dams was

introduced by the engineers Messrs. Bell & Miller, C.E., of Glasgow.

The method adopted was to “form the walls under low water of a

combination of cast-iron guide-piles in the front, with a continuous

stone-facing slid down over and inclosing these, and of concrete

backing deposited in a soft state;” timber bearing piles being used

where required, the walls from the low-water line being carried up

of masonry. The ground was found to be unequal, the upper being mud

and sand, further down red “ till.” The concrete employed was formed

of Arden hydraulic lime (a useful material obtained to the south of

Glasgow), iron-mine dust, sand, gravel, and stone chips.

The new works wholly or partly completed, comprise:

The Garvel Basin, area 6 acres, width of entrance 175 ft., depth at

low water 25 ft. The Great Harbour, area 45 acres, depth at low

water 28 ft. The James Watt Wet Dock, water area 14 acres: two

entrances of 75 ft. each, depth on sills 32 ft. Garvel Graving Dock,

G35 ft. in length, width of entrance GO feet G inches, depth on sill

20 feet.

From the Annual Report of the Clyde Trustees for the

year ending June, 1887, it appears that the total imports at Glasgow

from foreign ports was 1,1 GO,598 tons; coastwise, G4S,010 tons;

whilst the exports during the same time were: to foreign ports

1,202,27G tons, and coastwise 712,174 tons.

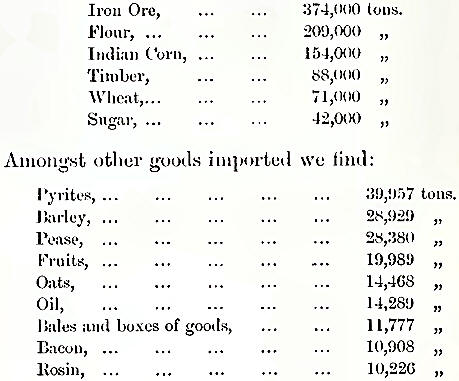

The goods imported consist mainly of

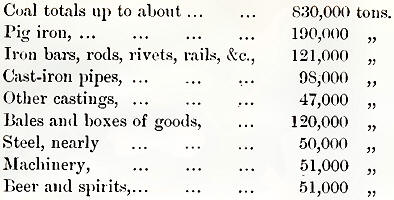

Of goods exported coal, iron, and machinery have the

chief place. Thus—

Amongst other articles exported from Glasgow were the

following:—

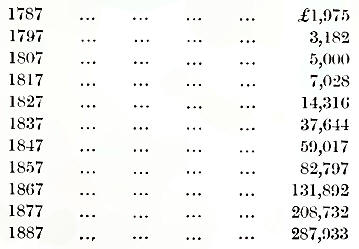

The annual revenue of the Clyde Trust in ten-year

periods, from 1787, is as follows:—

From 1752 to 1770 it was only £147, in 1771 it was

£1044, and the total revenue to 1887 is £7,107,281. This revenue was

mainly derived from dues on vessels and on goods. The annual revenue

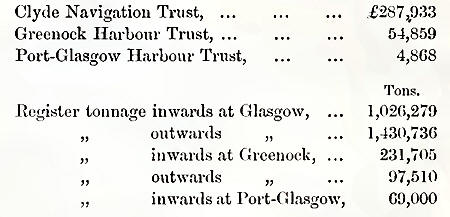

and tonnage of the ports on the river appear to be as follows:—

The revenue of the Clyde Lighthouse Trust appears to

be €12,070.

Measured miles2 have been laid olf at Skelmorlie and

in the Gareloch, where trials of the speeds of vessels can be made,

the time being taken as the steamer passes the extremities of the

measured distance, which are marked by two tall posts. It is also

customary to test the speed by running the lights, or taking the

time occupied on the run between the Clocli and Cumbrae Lighthouses;

this distance is 13'666 knots, or 15‘736 statute miles. Buoys for

compass adjustment are laid down in the Gareloch.

The question of the relation existing between speed

and resistance has of Bate years been ably investigated both

experimentally and mathematically, amongst others by the late Dr.

Fronde of Torquay, and by two well-known Clyde ship-builders, Mr.

Robert Mansel and the late Mr. William Denny. Dr. Froude’s

experiments were carried out in a large tank 270 feet long by 36

feet broad and 10 feet deep, containing suitable mechanism for

moving the models. These latter varied in size from 6 feet to 20

feet, and were made of paraffin.

Messrs. Denny, at their ship-building works at

Dumbarton, have constructed a large tank for the same purpose, with

special machinery for recording the results obtained, and also for

making the models.

The principal elements of ship resistance, as

determined by Dr. Froude, consisted in frictional resistance of the

skin of the ship, eddy resistance, and wave-making resistance.

Much useful information as to power and speed has

been derived from progressive speed trials, due largely to the

labours of the late Mr. Wm. Denny, and from diagrams constructed of

the results obtained. Thus, if the speeds are set off to scale on a

horizontal line, and the corresponding power required to drive the

ship sets off as verticals, the curved line joining the upper ends

of these vertical lines will show the relation between the speed and

power. Mr. Mansel, in analysing these relations, takes the

logarithms of the ratios of the different powers and speeds, and

uses these for the verticals raised at the corresponding speeds, the

result being that the relation between these verticals and the

horizontal distances is now shown by a straight line more or less

inclined.

Mr. Mansel, in treating of this subject, says: “In a

given steam-vessel under experiment, if we carefully measure various

rates of development of the power, and note for each the

corresponding rate of speed of the vessel, the normal law of the

relation of these elements, power and speed, can be stated thus:—The

logarithms of the ratio of the power to the speed, drawn as

ordinates to the speed laid off* as abscissa3s, will range in a

straight line inclined to the axis.”

In a paper read before the Greenock Philosophical

Society in 1882, on “The Speed and Carrying of Screw Steamers,” the

late Mr. Win. Denny explains in a very lucid manner the law of

comparison between the ship and model. He says: “What Mr. Froude

discovered amounts to this—that for vessels of the same

proportionate dimensions, and of the same form, or, as we say, of

the same lines, there are speeds appropriate to these vessels which

vary as the square root of the ratio of their dimensions, and that

at these appropriate speeds the resistance will vary as the cubes of

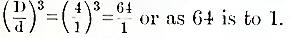

these dimensions.” He then goes on to illustrate this, and takes the

case of two steamers, the linear dimensions of one of which are

four times greater than the linear dimensions of the

other. Thus if the length of the first is taken as 400 feet the

length of the other is taken at 100 feet, the breadth of the first

being 40 feet that of the second is 10 feet, and if the draft of

water of the first steamer is fixed at 20 feet the second will be 5

feet; the appropriate speed for these vessels will therefore be that

is, the speed of the larger vessel should be twice the speed of the

small vessel. And so Mr. Denny says: “What Mr. Froude would have

predicted of these two steamers is—that if the speed of the smaller

steamer were 10 knots, then the similar appropriate speed of the

larger steamer would be 20 knots.” At these speeds Mr. Froude proved

that the resistance, with some allowance, would be as the cube of

the steamer’s dimensions, which would give for comparative

resistance with these figures, as

This, as Mr. Denny points out, “means practically

that the resistance would vary as the displacement of the two

steamers;” so that, in the case illustrated, the speed is doubled

without adding to the resistance per ton of weight, and that

consequently at a lower speed the large steamer would have a very

much less comparative resistance; hence, “in the same type of

steamer, by simply increasing all the dimensions proportionately,

the same speed can be obtained with much less resistance per ton of

weight driven through the water—that is, since the speed remains

unchanged, much less expenditure of horse-power, and consequently

much less expenditure of coal per ton of weight driven.” |