|

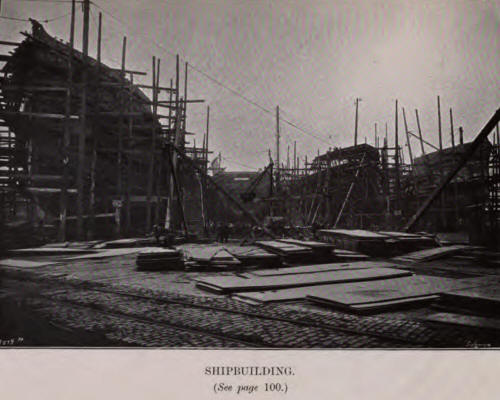

HAVING reviewed the history of the firm, and dealt briefly with the

results obtained by some of the modern steamers constructed by them, we

propose now C to describe the Works in order to indicate the measures

adopted to secure efficiency in design and construction of all types of

ships and machinery. Organisation and administration are as important

factors towards this end as the mechanical methods and appliances adopted,

and it may be well, therefore, to deal first with these.

The firm have been responsible for the design of almost every merchant

ship constructed by them. Success has been rendered more certain by the

possession of carefully- collated records, the product of an organised

system of working up all data, of tackling new problems, of making

calculations regarding any scientific question, and of studying

contemporaneous work as described in the technical press and in papers

read at technical institutions. This continuous investigation produces a

wealth of suggestion, which enables the chiefs of the respective

departments to determine how far practice may be improved; and thus there

is steady progress not only in design but in constructional methods. A

well-selected technical library, from which the staff can borrow books,

also contributes to the same end.

Admiralty and merchant work is initiated in separate drawing-offices. The

"Printed Instructions to Draughtsmen" throws light on the general

principles which influence design, and one or two quotations may be

made:-" Every machine or structure is designed with a certain object in

view; therefore, in designing, keep that object always to the front. Go

straight to the point, and let the object be attained in as simple a

manner as possible. Avoid all curves and indirect lines, except those

conceived to give uniform strength or stiffness, or required for some

definite purpose. There should be a reason for the contour and shape of

every detail. It should be remembered that designs made in this way,

requiring least material for the work to be done, usually look best.

Besides keeping the object clearly to the front, it is necessary in

designing to remember that certain facilities must be attended to for

moulding, machining, and erecting. It is also necessary to keep in view

the circumstances in which the structure or machine is to be used. Every

little detail should be definitely attended to on the drawings, and not

left to the judgment of the men in the shops; remember that it is usually

the unexpected which happens, and that even the want of a split pin may

cause a breakdown. In making drawings or sketches for ordering material or

for the shops, assume that those who have to interpret the instructions

have no knowledge of, or information concerning, the work in question,

except what is contained in the drawing or order you are making out. This

will ensure that all information issuing from the drawing-office is

complete, and that no work is done in the shops without drawing-office

instructions."

The draughtsman, in designing work, must so arrange details as to fully

utilise, as far as is compatible with progress, the special machine tools

available, the system of gauges, templates, and jigs extensively applied

in the shops, and existing patterns. Bonuses are paid for improvements in

design whereby economy may be effected in machine operations, etc.

There is a large estimating department, where records of costs, rates,

wages, etc., are of the most complete description. The card system adopted

is admirably suited for enabling references to be made at any time as to

the cost of units in any contract. Here also it is possible, by the simple

process of comparison, to effectually check the economy of design and

manufacture, without which a high premium is placed against efficiency.

The staff in these departments is largely recruited from the shops, and

thus there is an incentive to the willing apprentice to excel. The great

majority of the vacancies in the technical staff are filled by apprentices

who have spent three and a-half years in the shops, and who are chosen as

a result of examination and of a satisfactory record in the shops.

Financial facilities are afforded to boys and to progressive workmen to

attend special classes, not only in Greenock but in Glasgow. Competitions

are instituted at intervals to encourage expertness in some branch of

work—for instance, in the use of the slide-rule, etc. Thus in many ways

the growth of an active esprit de corps is encouraged, apart altogether

from the influence which the historical and present-day success of the

firm engenders.

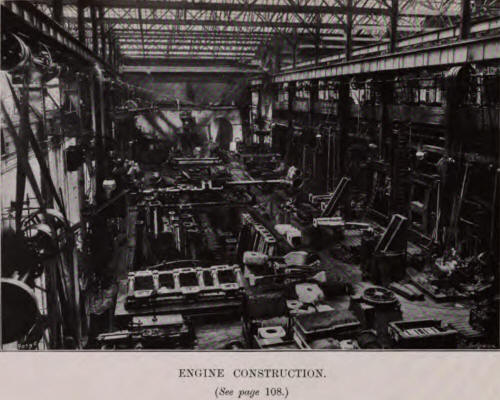

The same broad policy is pursued in the shops. Payment by merit to the

tradesman is adopted as far as possible. In the engine works the bonus

system—first adopted in 1902—is extensively applied. The arrangement is

satisfactory from the point of view of tradesman employer, and client.

Long experience has enabled the firm to set equitable standard times for

many operations, and there was from the beginning the guarantee that this

standard would not be altered unless entirely new machines were introduced

to greatly influence the rate of production. Now if a workman requires the

full time, or more than the time set as a standard for a job, he is still

paid his full-time wage as under the old conditions : but should he

complete the work in less than the standard time, his rate• of wage per

hour is increased in direct proportion to the saving in time; the shorter

the time taken, the greater the rate of bonus. The bonuses earned range as

a rule from 20 to 30 per cent. over the time-rate wage. To quote actual

cases, a workman who saves 26 hours on a job for which the standard time

is 134 hours, increases wage for the fortnight by 14s., while the money

saved to the employer is only 2s. 9d. He who saves 30 per cent. on the

time adds 21s. to his fortnight's wage.

Such reduction in the time taken is not attained at the expense of

efficiency; the premium job is carefully inspected, and unless it is of

the highest standard the bonus is forfeited; so that the workman is

continuously careful to avoid any risk which will result in the loss of

the reward for his extra work. The reduction in time taken is, in a large

measure, due to the exercise of foresight and ingenuity on the part of the

workman. He is ever on the alert to ensure that he will not be kept

waiting for material to enable work to progress. The machine-man makes

certain that before one unit is out of his machine the casting, forging,

or bar for the next is alongside. This is further facilitated by a man in

each shop whose only duty is to see that there is a supply of work for

every tool. Encouragement is always accorded to those who suggest

modifications to increase the output from any machine. Again, in the

erecting of engines, considerable economy has been attained, owing to

similar foresight being exercised to ensure that each unit is machined

before it is wanted by the erector, To the employer also there is gain in

the increased production, from a given number of machines and men, for a

constant establishment expenditure—rent, rates, taxes, etc. While the wage

paid to the men is increased, there is a reduction in the cost of

production, which of itself encourages capital expenditure on improved

methods and appliances. Concurrently with the adoption of the bonus system

there has been a great increase in the cutting speed of tools, which has

also augmented the rate of production. This "speeding-up" is partly due to

the fitting of new machines, to the substitution of forged steel machine-.

cut gear for cast spur - wheels, to the strengthening of lathe headstocks,

to wider belts, to the application of reversible motors to some machines,

and to quicker return speeds.

Some indication may be given of the increased economy resulting from the

bonus system and from the "speeding- up" of tools, as compared with the

former system, with slower speeds and piece-work rates. A typical job,

which had formerly occupied eighty hours, was, after experience, given a

standard time of sixty hours. When first carried out under the bonus

system the time actually taken was forty-five hours, the labour cost being

reduced from £2 13s. 4d. at piece-work rate to £1 17s. 6d. under the bonus

system, while the wage of the worker was increased by 2d. per hour.

Subsequently, a repeat of this job was machined by the same man, who,

having confidence that the time allowed would not be reduced, finished the

work in thirty - nine hours, saving twenty - one hours on the standard

time, reducing the cost to £1 15s. 0d., and increasing his rate of pay by

2.8d. per hour. Other comparisons might be given to show the advantage

over the piece-work. In successive fortnights after the introduction of

the system, the percentage of time saved on the time taken on piece-work

in one department steadily advanced from 16 per cent. to 47 per cent., and

ultimately the pay of the men per hour was increased 75 per cent., while

the saving to the employer was 50 per cent.

The client profits, as the contract price is reduced without any

diminution in the satisfactory character of the work done; indeed it is

probable that this is improved because of the special inspection to

ascertain if the bonus has been conscientiously earned. A lower contract

price, therefore, is possible; and this places the firm, both directly and

indirectly, in a better position in competition in ship-building. There is

more work obtainable, more constant employment for the workmen, with the

additional inducement of higher wages to capable and diligent men.

|